If you’re into building FPV drones, then choosing the right frame is crucial for both performance and durability. In this ultimate guide on FPV drone frames, we will discuss the different types of frames available, factors to consider when selecting a frame, and everything else you need to know to choose the perfect FPV drone frame that suits your specific needs.

Frame Recommendations

Here are my 5″ freestyle frame recommendations for your custom builds.

AxisFlying Manta 5 SE

The AxisFlying Manta 5 SE frame is my top pick for 2024, especially for those who don’t own a 3D printer and need a ready-to-go 5-inch FPV drone frame for freestyle, cinematic, or long-range flying. Despite its affordable price, this frame stands out for its combination of features, ease of use, and aesthetic appeal, making it an excellent option for pilots of all levels.

The Manta 5 SE features a split deck design that reduces weight while maximizes room for mounting your FPV camera. Various mounting patterns for different sizes FC and VTX. The included 3D printed accessories make this frame versatile for both beginners and experienced pilots. Learn more about this frame in my review: https://oscarliang.com/axisflying-manta-5-se-frame/

Find the Axisflying Manta 5 SE from:

GetFPV: https://oscarliang.com/product-lnot

AliExpress: https://s.click.aliexpress.com/e/_omqpGWT

RDQ: https://oscarliang.com/product-2izg

Source One V5

The TBS Source One V5 frame is one of the cheapest FPV drone frames available from a well-known brand. Its popularity lies in its open-source nature, allowing for a wide range of TPU accessory designs available online, provided you have access to a 3D printer. Spare parts are also readily available, adding to its appeal. The frame’s simple yet effective design delivers decent flight performance and durability.

However, it includes only the bare minimum of parts. To get the most out of the Source One V5, I recommend downloading and 3D printing some TPU parts from platforms like Thingiverse. Learn more in my detailed review: https://oscarliang.com/source-one-v5/

Where to Buy the TBS Source One V5 Frame:

GetFPV: https://oscarliang.com/product-dg3f

AliExpress: https://s.click.aliexpress.com/e/_DEidP4J

Amazon: https://amzn.to/3U1wyt8

RDQ: https://oscarliang.com/product-nf0f

FlyFishRC Volador

The FlyFishRC Volador is a well-designed frame that emphasizes originality and attention to detail, making it an excellent choice for building an FPV drone with an O3 air unit. However, its assembly might be a bit more complex compared to other frames due to the number of components, which could be daunting for beginners. Additionally, the Volador frames are on the heavier side, which may not appeal to those prioritizing performance.

That said, for pilots who value a clean and organized build and don’t mind the additional weight, the Volador frames are worth considering. The inclusion of all necessary TPU parts is a thoughtful addition, especially for those without access to a 3D printer.

Volador VX5

AliExpress: https://s.click.aliexpress.com/e/_Ddkfu2Z

Banggood: https://oscarliang.com/product-kl48

Volador VD5

AliExpress: https://s.click.aliexpress.com/e/_Dl4NyVf

Banggood: https://oscarliang.com/product-kl48

What is a FPV Drone Frame?

An FPV drone frame is the structural backbone of a drone. It is the skeleton on which all other components are mounted, and provides protection to all the electronics inside the drone.

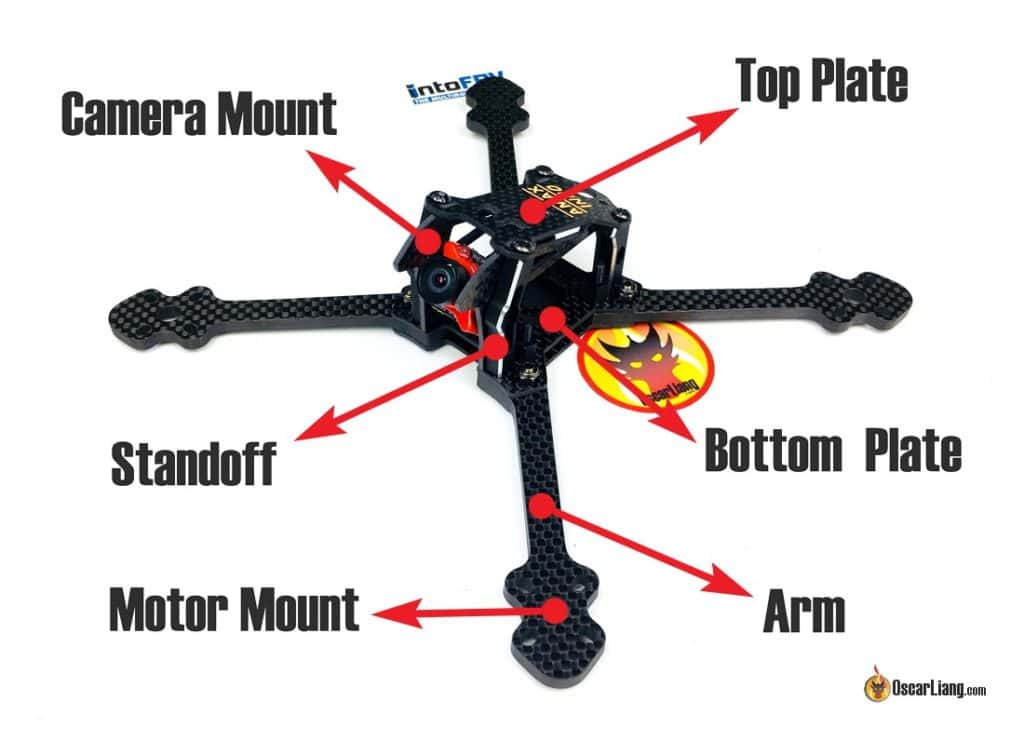

A typical FPV drone frame is made of carbon fibre plates and metal hardware:

- 4x Arms

- Top and bottom plates

- Camera mount

- Standoff

- Bolts

Most frames have similar shape and construction, but the FPV drone frame you choose can have noticeable impact on the flight performance of your FPV drone. Not only just weight and aerodynamics, the resonance frequency and rigidity can affect how well the drone can fly.

Anything that isn’t specifically designed for racing is often considered a freestyle frame which you can use for almost everything like flying freestyle at a bando, carrying a GoPro for cinematic shots or just having fun cruising at a local park.

Race frames are designed for pure performance at the expense of almost everything else – light weight and minimal surface area for low drag. This tends to make race frames more difficult to build and repair. They are less durable and provides less protection for the components.

This is a race frame.

Generally if you don’t race, you probably want to opt for a freestyle frame, which is way more durable and versatile.

This is a freestyle frame.

The Ideal Frame

There’s no such thing as “best frame for everything”, it all comes down to the requirements and application.

The ideal FPV drone frame should be strong and practical while being as light weight as possible. If you want more protection, the frame would use more material thus become heavier. If you want higher degree of practicality, you’d use more accessories which adds weight. If you want to keep the weight down, then you’d have to make sacrifice to both durability and features. We just can’t have it all, you should prioritise what’s more important.

Many FPV drone frames today adopt a minimalistic design, featuring skinnier arms but thicker carbon. This trend primarily focuses on weight savings and reducing “low frame resonance.” In my opinion, frame resonance is inevitable, but having a solid frame without any loose parts should simplify the tuning of filters substantially. It’s crucial to remember that Betaflight has been evolving alongside these frame designs. Therefore, it’s not solely the frames that enhance our quads’ performance but also the advancements in flight software.

Material

Carbon fibre is the most popular material for FPV drone frames because:

- Low cost: makes it accessible to a broad range of pilots, from beginners to professionals.

- Light weight: a lighter racing drone means faster speed, better agility, longer flight time, and less destructive inertia in a crash.

- Durable: it can withstand the high stresses and impacts that drones encounter during flights and crashes.

- Rigidity: CF has high stiffness to weight ratio. Frame rigidity is important for tuning and flight performance.

- Highly customizable: it allows manufacturers to produce frames in various shapes, sizes, and thicknesses to meet the specific needs of different pilots and flying styles.

The downsides of carbon fiber are:

- Carbon fiber is electrically conductive: If you have live wires touching the frame it could cause a short circuit and burn out components.

- It can block/attenuate radio frequencies, antennas should be mounted outside of the frame for optimal signal strength.

There could be a substantial weight and cost difference when using different metal alloy for bolts/nuts/hardware. Steel is the cheapest and strongest option but also the heaviest. Aluminium is the lightest, but also the softest and tends to bend in a crash, and strip easily when too much torque is applied. Titanium is light weight and strong but expensive. I have an article covering the different metals used for bolts in more detail.

Construction

A drone frame has two main parts: the body and the arms.

The body houses and protects your electronic components including flight controller, 4in1 ESC, FPV camera, VTX etc. Typically it consists of a bottom plate, top plate and some standoffs in between to hold them together.

The arms are for installing the motors on. The shape and thickness play a huge role in the durability of the frame, because the arms tend to be the first place to break in a crash.

Frame Size

Quadcopter frame size (a.k.a. wheelbase) is the diagonal motor to motor distance measured in millimetres. It dictates the size of propeller you can run on it, therefore the frame size often are referred to the maximum propeller size it can support, instead of its wheelbase. For example, when people say “a five-inch frame,” it means the frame is sized for 5″ props.

As the motors are mounted on the very end of the arms, the further away they are from the centre of rotation, the larger the moment of inertia would be. It introduces a tendency to resist angular acceleration and deceleration and makes your quad feel more sluggish and less responsive. Therefore you want to use the biggest propellers a frame can support to maximize its performance. If you run 4-inch props on a 5″ frame, it would not perform as well as on a 4″ frame.

Here is a table showing roughly what maximum prop size different mini quad frame sizes can support:

| Frame Size | Prop Size |

| 280mm+ | 7″ |

| 220-250mm | 6″ |

| 180-220mm | 5″ |

| 150-180mm | 4″ |

| 120-150mm | 3″ |

| 90-120mm | 2″ |

Configuration

A typical frames are made up of various parts: 4 arms, 2-3 top/bottom plates, hold together by standoffs and bolts.

The arm layout refers to how the arms of the FPV drone frame extend from the body. It might look like some of the motor layouts are similar (they are all rectangular after all), but it does have an effect on control feel and flight performance. There are some other reasons too when choosing one particular motor layout than another.

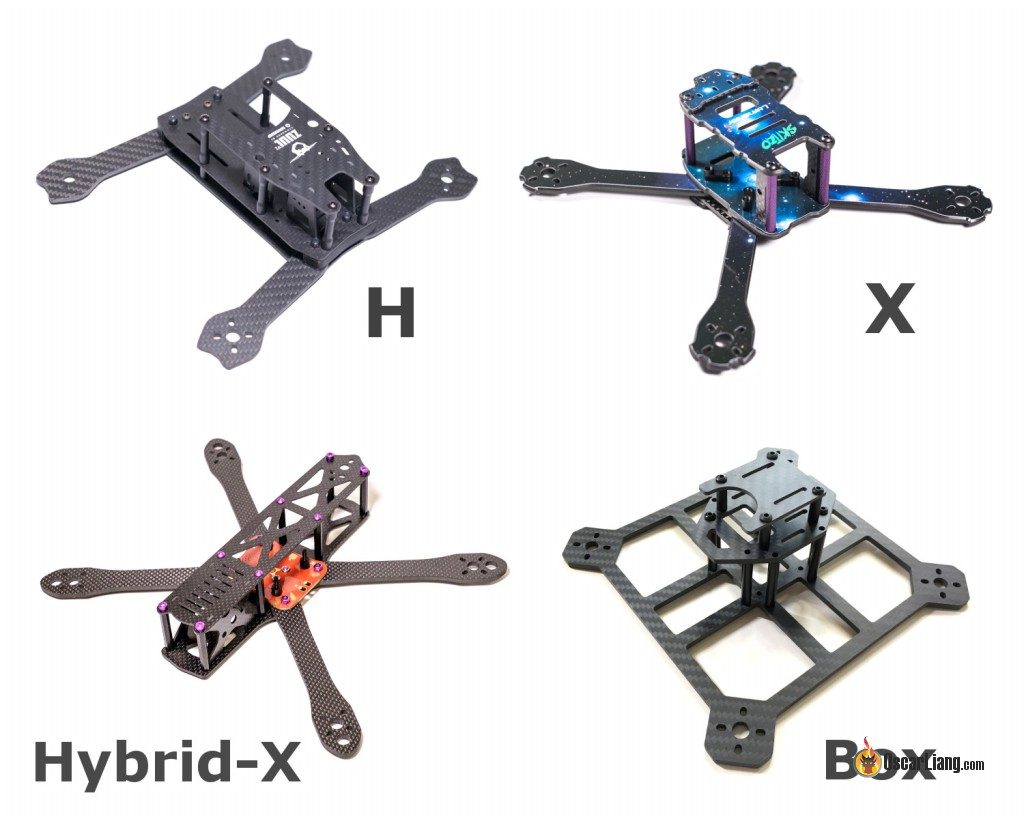

H Frames

On an “H” frame, the front and back arms are perpendicular to the middle plate, forming an “H” shape. This leads to a long and roomy body section for installing your electronics comfortably, makes it very easy to build. HD camera and battery can both sit on the top plate, the weight of the quad is more spread out. For this reason, it might feel less agile than X frames due to higher moment of inertia on the pitch axis.

In recently years the hobby has mostly moved to the X frame designs.

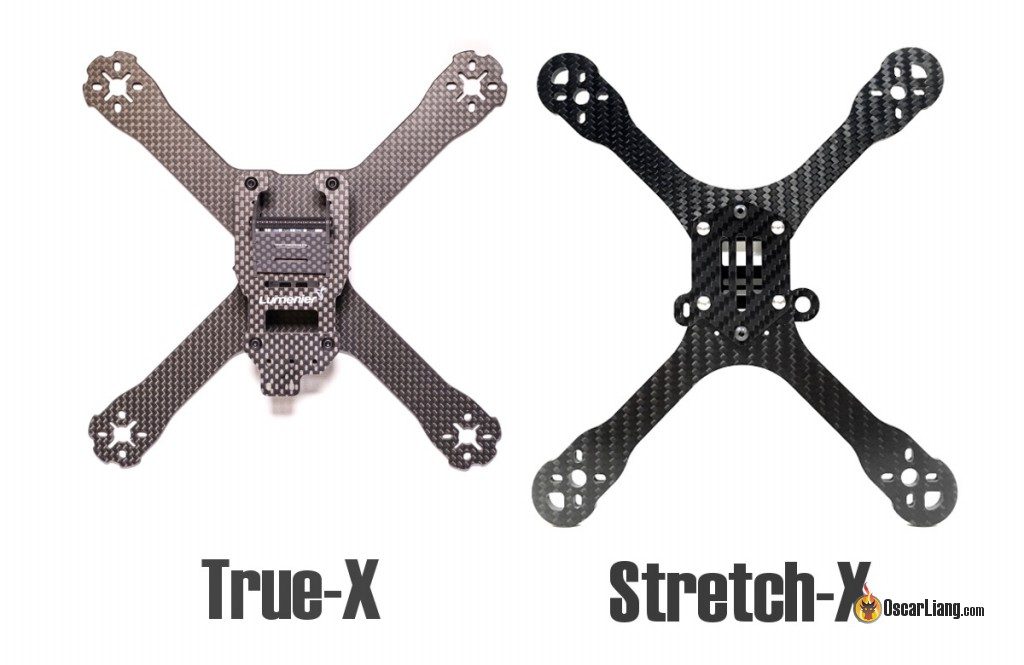

True-X Frames

On a “True-X” frame all the arms intersect at the centre forming an “X” shape, with equal distance between all the motors to the center of the frame. True-X frames tend to have a more neutral handling and balanced behavior on pitch and roll as the motors are contributing equally.

Some argue it has little to no difference to an H frame in terms of flight characteristics, since the mass distribution is the same, while others claim there is a difference to how the thrusts are applied on the frame due to the way the arms are connected to the body (think about leverage). Also the ways vibrations are transferred to the FC through the arms could be different.

Stretch X Frames

Similar to the “True X” frame, but with the front and back arms stretched farther apart than the side arms. The idea is to reduce air disturbance that the rear propellers get from the front propellers, and it might also improve handling at high speeds and in tight turns.

Deadcat

Deadcat geometry refers to a motor layout that is asymmetric, meaning the motors are not symmetrical front and back. This layout is designed to keep the propellers out of the camera’s view, making it an attractive option for capturing cinematic footage.

However, due to the asymmetrical motor layout, pilots may experience a slight amount of yaw mixed in with roll movements. While the mixer in your flight controller can usually compensate for this, the result may not be perfect all the time. The impact of this issue largely depends on your flying style and rates. For smooth cinematic flying, this downside is generally negligible. However, for pilots who prefer high rates and aggressive freestyle maneuvers (such as doing acrobatic moves), this mixing can be more noticeable and problematic.

Another downside of deadcat frames is their crash durability. Due to their design, deadcat frames have a higher chance for the camera to take a hit during a crash. This is an important factor to consider when deciding whether a deadcat frame is the right choice for your drone setup.

Box Frames

A box frame is pretty much an enclosed X Frame. This basically creates a tougher frame that is less likely to have broken arms. However the extra material creates more drag and weight. Not the best choice for performance but definitely helps improve strength of the arms.

Plus Frame

Instead of flying forward like an “X”, a Plus Frame flies forward like a “+” sign. There may be some benefits with regards to motor turbulence though, because the side motors on a plus frame will always be spinning in clean air. One of the downsides is the front motor and propeller can easily get in the view of the camera. It’s not common frame type apart from the fact that it looks unique and is eye-catching..

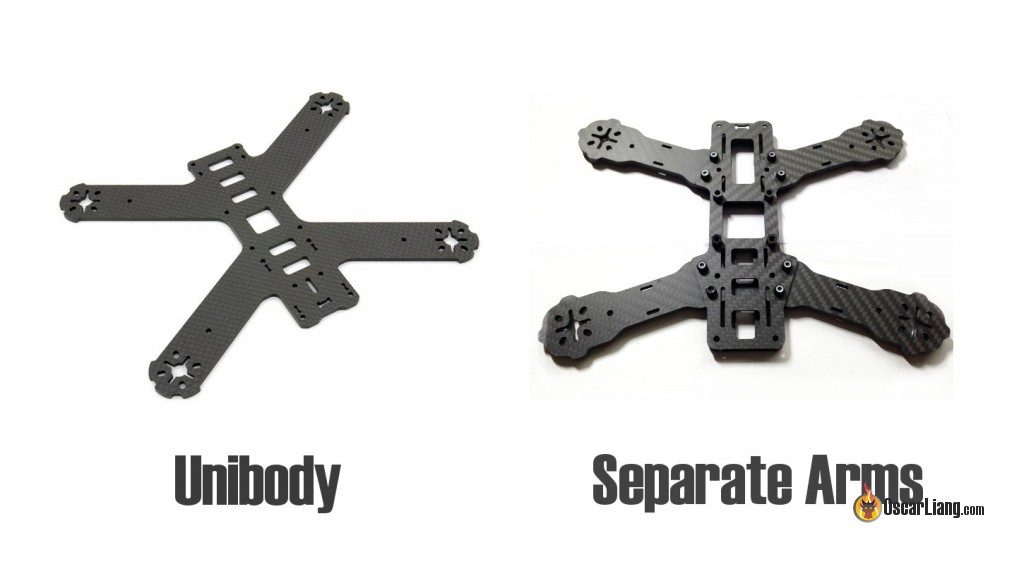

Unibody Design

Some frames have all the arms and bottom plate cut from a single piece of carbon fiber sheet, this is often referred to as a unibody design.

A frame can be designed to have separate, replaceable arms, but it involves extra hardware such as bolts, nuts, and an extra bottom plate.

Unibody is much lighter and makes frame assembly easier, but if you break one arm, you would have to replace the whole bottom plate and move all your motors across to a different frame, it’s a lot of work. In comparison, with separate arms you can simply replace the broken arm.

As for rigidity, I generally find frames with replaceable arms stiffer than a unibody, because the arms are usually sandwiched between two separate plates. But of course, arm stiffness depends on carbon fibre width and thickness too.

Durability

Carbon fibre quality: Cheap frame from unknown brands will most likely use low quality carbon fibre and it’s probably not going to hold up well to crashes. Unfortunately, there’s no easy way to tell by just looking at pictures of the frame. The best you can do is to check out reviews and base your judgement on the frame’s price tag and the brand’s reputation.

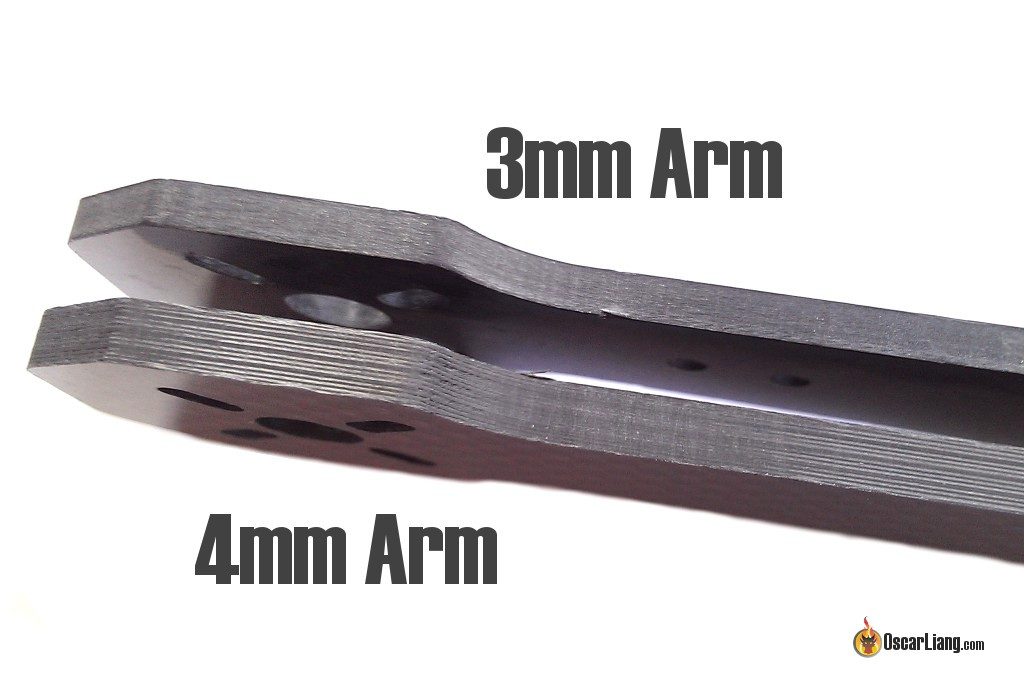

Arm thickness: In general, a thicker arm is less likely to break because more material provides a wider area to distribute stress over in a crash.

Stress points: avoid arm design that involves hard angles as it’s much easier to break in a crash, curves and round cutouts are much better for strength.

Weaves direction: there are weaves in carbon fibre sheet, and the cutting direction actually makes a different to the strength. The carbon fibre plates are stronger when cut along the weaves and weaker when it’s cut at 45-degrees to the weaves.

Carbon Fibre Thickness

Thicker carbon fiber means better strength, rigidity and sturdiness, but it also gets heavier.

Durability matters most on the arms, as they take most of the strain in a crash. This makes it common to see top, centre and bottom plates cut from thinner 3mm or even 2mm CF.

Arms in 5″ frames commonly used 5mm arms (thickness), but advancements in motors have made thicker 6mm more common, to withstand the greater forces of higher speed impacts. For 5″ frame you should be looking for at least 5mm thick arms, for light weight 3″ and 4″ you may go down to 4mm or even 3mm. For 2″ just 2.5mm (or even 2mm) is possible. Any thinner than this will break too easily and probably too flexible too for decent flight characteristics.

Filing Carbon Fibre Edges

If the carbon fibre in your new frame don’t come with chamfered edges, then you could consider filing those rough and sharp edges yourself. It’s not only for the better look and feel, but also for the following practical reasons:

- Sharp edges can cut through wires, LiPo straps, etc if they are rubbing against it over time

- Chamfered the edges, and then applying Cyanoacrylate glue (CA) can prevent the carbon fibre from delamination in a hard crash

In this tutorial I will show you how to prepare a carbon fibre frame by filing the edges. It’s best to do this under running water to avoid breathing in CF dust, the ultra fine particles are harmful to your lungs.

Flying Styles

Frames are designed for specific application and flying styles, usually stated in the product description. The flying styles are:

- Freestyle

- Racing

- Long range

- Cinematic

With that being said, there’s no hard rule what frame you must use for what purpose. You can totally race with a freestyle frame, or you could freestyle with a racing frame.

If you are just starting out, I would recommend a freestyle frame as they are versatile, generally easier to build thanks to the roomy body, and they are relatively durable against crashes.

Battery Mounting

Should we put LiPo battery on top of or underneath the frame?

Here is a more in-depth discussion whether it’s better to mount your battery on top or bottom.

For freestyle builds, I normally have the battery mounted on top for 2 reasons:

- Centre of mass is closer to the level (or plane) of the propellers, where the force is generated. This reduces the moment of inertia when rotating, it also makes the quad handle corners better in my experience

- Landing on the battery repeatedly can damage it (crashing is a different matter, you never know which side will take the blunt of the impact)

Most racing frames opt for bottom mounted battery due to the lack of space on top.

Other Considerations

Aesthetics

There’s not much to say here other than that we think this is an important consideration when building an FPV drone. You should build a quad that you like aesthetically. Choose your favourite frame! If you are passionate about something, all other factors becomes less significant.

Weight

The weight of a frame comes down to how it’s designed, how much material is used and what sort of hardware is used. 5″ racing frames weigh in between 60–90g on average while freestyle frames often weigh in between 90–120g.

Apart from shorter flight time, a heavier weight does mean carrying more momentum into a crash. The heavier quad takes a harder impact for the same amount of speed as compared to a lighter one. Usually, this is more than offset by smart design, but it’s worth noting that weight in itself does not provide durability.

FPV Camera Mounting

There are 2 main FPV camera sizes: micro and nano. Make sure if the frame supports the camera size you are planning to use.

Find out what kind of camera tilt angle is allowed in the frame. Camera tilt angle affects how fast you can/want to fly your quad. For freestyle, 20-30 degree is quite popular, while some hardcore racers will tilt their camera all the way back at 60 degree. A tilt angle that is too low or too high can hugely affect your FPV experience, especially if you are a beginner. I think having a freestyle frame that allows you to easily adjust the camera angle between 0 degrees to 45 degrees would be ideal. If you are just starting, you should start with a lower angle like maybe 5 to 10 degree and slowly increase it as your progress.

FC Mounting

Make sure the frame supports the FC and ESC you are planning to use, most commonly FC’s have a mounting pattern of 30.5mm x 30.5mm, or 20x20mm. Smaller frames like 2″ and 3″ even support 25.5×25.5mm and 16x16mm FC mounting.

Rigidity

We have mentioned the importance of frame stiffness more than a dozen times . A well designed frame should be strong, crash resistant, yet rigid. If there is bending or warping in the arms during flight, your quad will be prone to problematic vibrations. As a result the quad can be hard to tune, and you might get jello in your FPV feed as well as the HD flight footage. If your quad suffers from vibration, the flight controller must work harder to stabilize the copter, and in extreme cases vibrations can even cause your motors to overheat.

HD Camera Mounting

If you plan to fly with an HD camera such as a GoPro or Insta360 GO2, make sure to check if the frame supports it. You might have to spend extra to get a 3D printed mount, or it might be included in the kit.

Spare Parts

No spare parts available means buying a whole new frame when you break an arm or top plate. If the frame you want to buy is expensive but doesn’t offer spare part, you may want to reconsider.

Motor Protection

Extra material around the motor mount could potentially protect your motors from damage in crash. but this does increase weight.

Evolution of FPV Drone Frames

Here are some of the most iconic FPV drone frame designs that offers original and unique features. If there are other frames you think I should feature here, please comment down below.

Released back in 2014, the Blackout frames were the beginning of 5inch mini quad. It was expensive even by today’s standard, and it was hardly available back then due to its popularity. Shortly after, the ZMR250 was released, which was heavily inspired by the Blackout, but it was much more affordable and easily accessible.

The Lumenier QAV frames were made popular by their sponsored pilot, Charpu. And then there was this cool looking, but very heavy Atas Defiance 265 and Robocat.

The Alien frame by ImpulseRC was another iconic frame in 2015, as it was one of the first True-X frames and endorsed by many top pilots at the time. The Armattan F series frames were also very popular in the same period.

The most popular FPV drone size settled at 5″, because it offers the best balance between power and agility. And since then “True-X” frames became the standard of 5″ frames.

Later we have frames with different camera pod designs and 3D printing started to play a bigger part in mini quad frames.

Different materials have been used in mini quad frames, such as the Ragg-E that uses super durable HDPE. On the other extreme, some frames tried to shave as much weight as possible by making skinny arms that looks like chopsticks, such as the X-foot or the QAV-ULX.

In the 2nd half of 2016, we started to see side plates structures replacing standoffs. The Armattan Armadillo and DemonRC Fury were great examples of that.

The beginning of 2017 saw the introduction of aluminium (and other metal alloys) into frame designs. These materials are often used to provide additional protection to the FPV camera and other components, they can also be anodized to add a flash of colour. The new designs create a strong structure yet looking awesome! Both of these frames, the DQuad Obsession and Armattan Chameleon have been featured in our recommendations in 2017.

Should You Buy Clone To Save Money?

No doubt, there are a lot of overpriced frames out there. And cloning is a real issue in this hobby because how cheap and easy it is to copy a frame design.

If all you could afford is the clone, then by all means go get it and have fun! But please try to avoid clones whenever possible, not just for the quality, it’s about sustainability.

It takes a company months to design, test and release a frame, it doesn’t cost the cloners anything. Especially so for mini quad frames, after all they are just pieces of carbon fibre, anyone with a CNC machine can do it. Therefore frame manufacturers inevitably suffer from copying and cloning. Cloners can sell their frames at half of the price or even lower, because they didn’t invest in R&D, and they often use cheaper material.

Edit History

- Mar 2017 – Article created

- Feb 2018 – Added plus configuration description and image, updated frame size image, added anatomy image, fixed various grammar errors

- May 2022 – Revised

- Feb 2023 – Added some more images