Revopoint, a global name in professional 3D scanning technology, is set to launch its latest innovation, the Trackit 3D Tracking Scanner, on Kickstarter. Designed to streamline workflows and eliminate the need for scanning markers, Trackit delivers high-precision results across a wide range of industrial applications.

Marker-Free Efficiency for Industrial Workflows

Trackit addresses a major productivity bottleneck common in traditional 3D scanning processes: the use of markers. Conventional systems often require time-consuming manual placement of adhesive markers on scan targets to maintain positional tracking. This step not only slows down the process but also introduces opportunities for misalignment, especially when scanning large or complex objects.

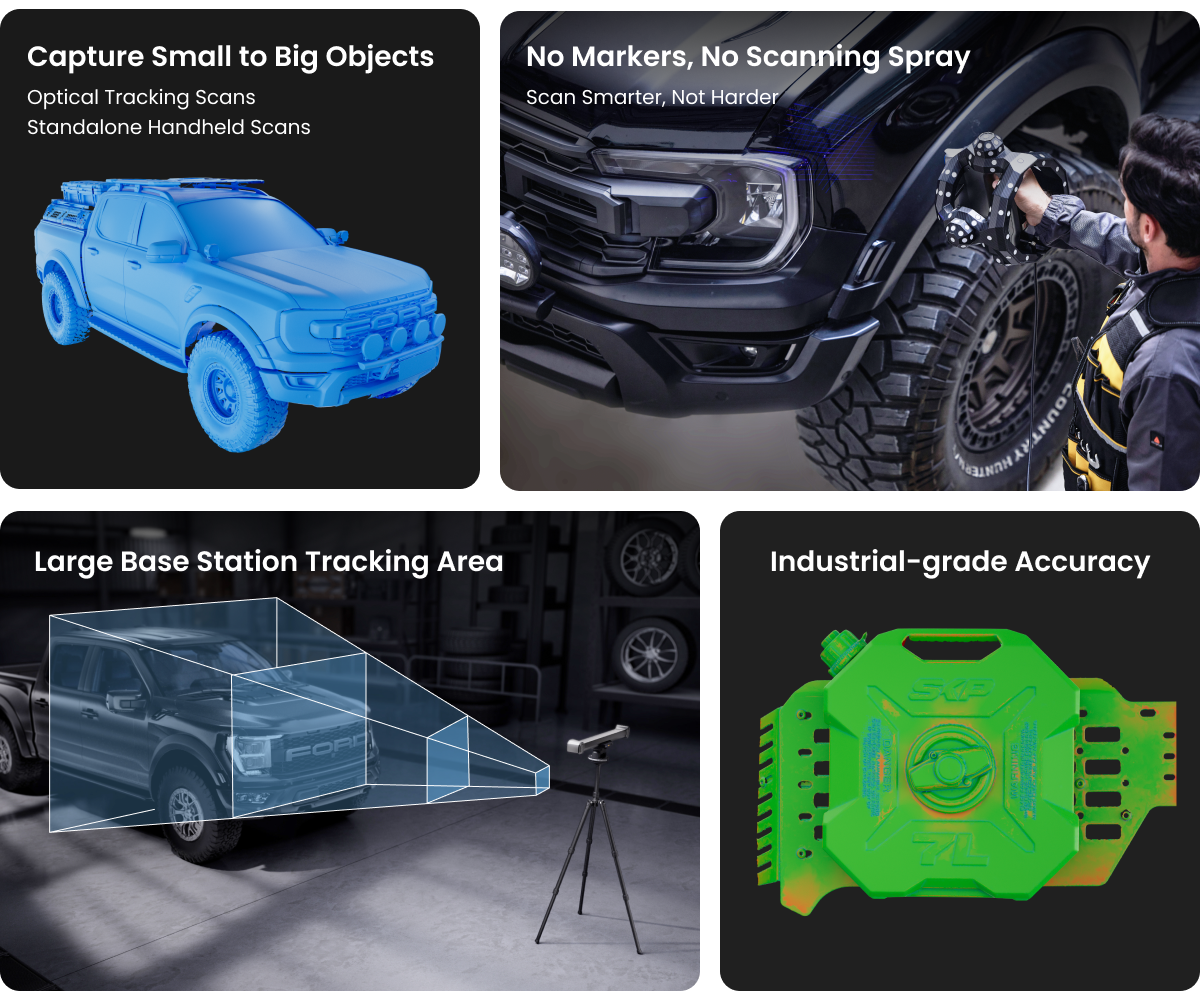

Trackit eliminates this issue entirely through an advanced optical tracking system. Its base station uses dual cameras to track the scanner’s position and orientation in real time. This system performs live error compensation to ensure positional accuracy throughout the scanning session, reducing cumulative errors and improving overall scan fidelity. As a result, operators can move freely around the object without interrupting the scanning process or recalibrating the setup.

The marker-free approach also enhances repeatability and reliability—two critical metrics in industrial workflows. By removing the variability associated with marker placement and environmental conditions, Trackit ensures consistent high-quality results with minimal operator input. This is particularly beneficial in applications like quality inspection, reverse engineering, and design validation, where precision and speed are equally important.

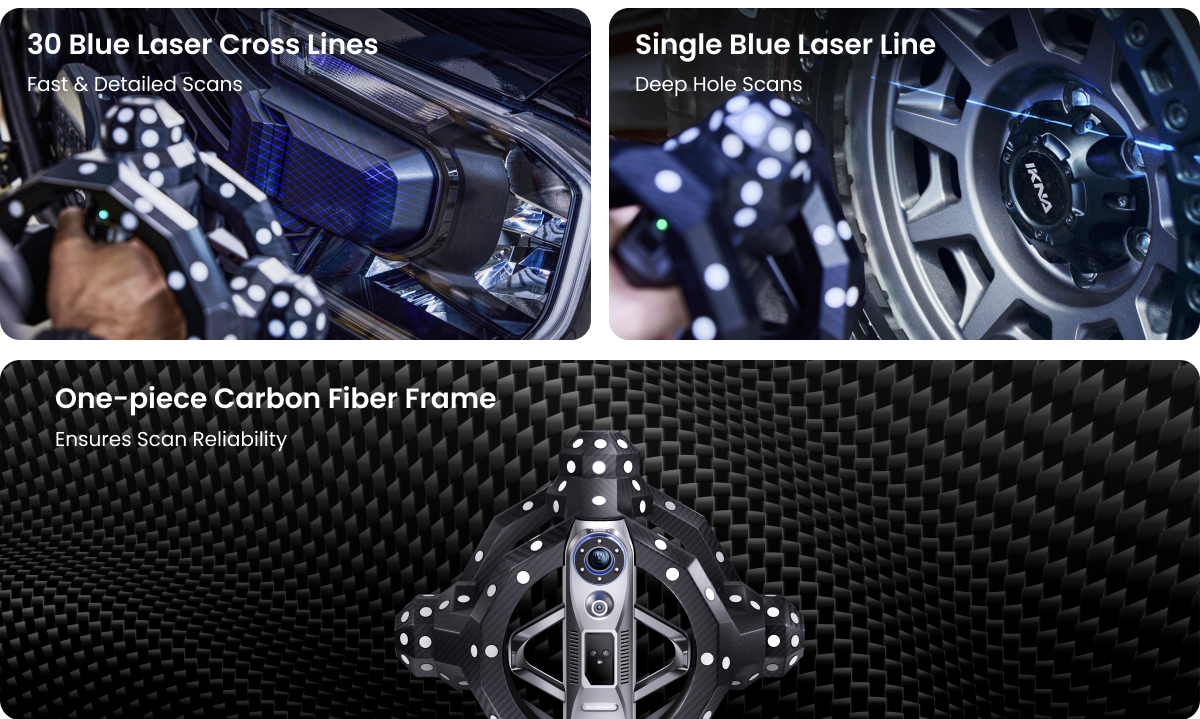

Its blue laser scanning technology further complements this workflow by capturing detailed surface data even on difficult surfaces such as shiny or dark-colored materials, which often present challenges for conventional scanners.

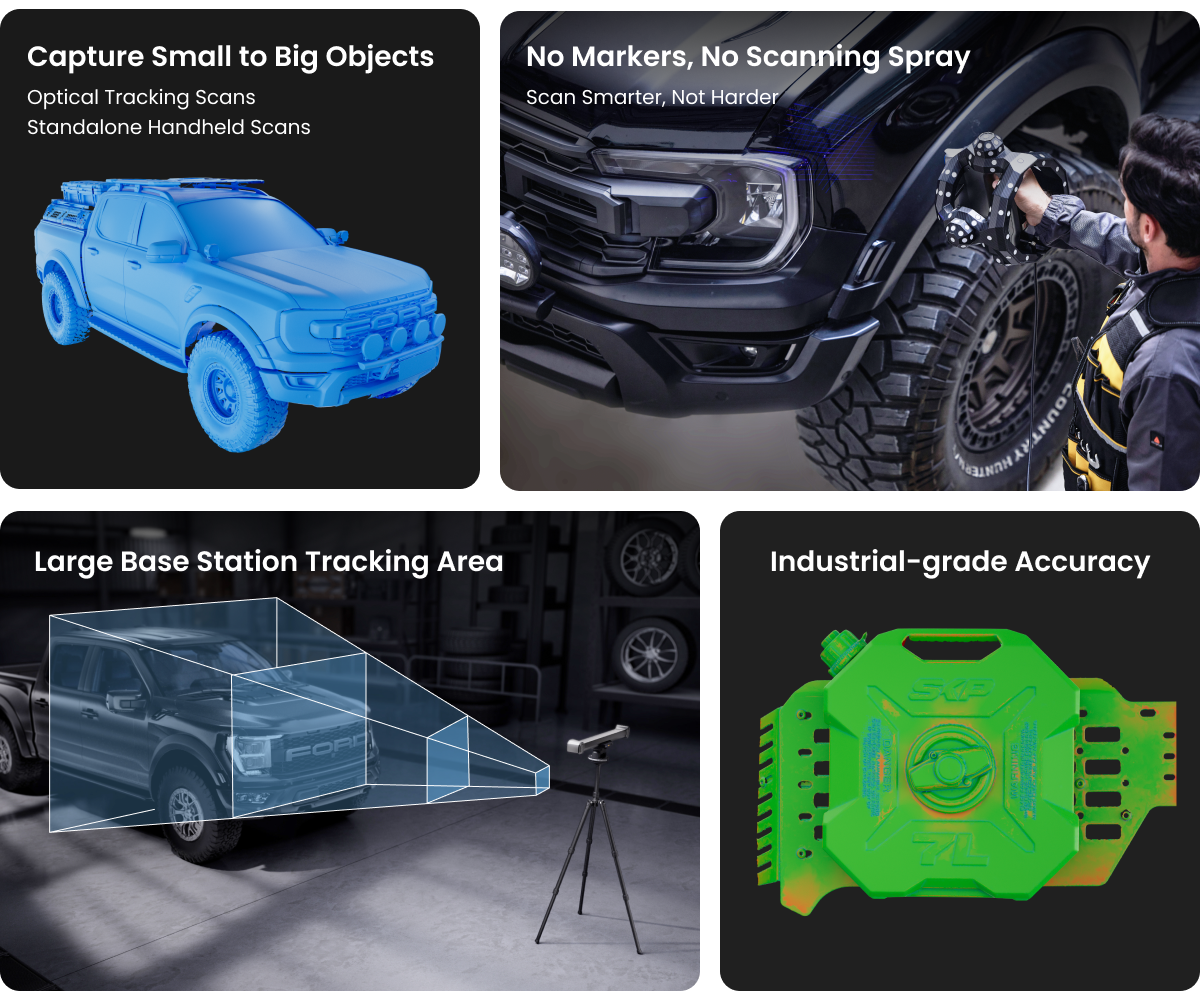

Designed for Small Parts and Large Assemblies

With its dual-mode scanning system, Trackit is equipped to handle everything from tiny mechanical components to full-scale vehicles. Its 30-line blue laser mode excels at capturing surface geometry—including dark and reflective areas—while a single-line mode is optimized for scanning deep holes and recessed features. For large-scale scans, Trackit’s dual-camera optical tracking base station can be repositioned to cover wider areas, making it ideal for industries such as automotive, aerospace, and heavy machinery.

Industrial-Ready Design for Demanding Applications

Trackit’s one-piece carbon fiber frame provides a foundation of structural integrity and scanning precision by eliminating potential frame deformation. This durable yet lightweight design ensures reliable performance in industrial settings and allows for extended scanning sessions without user fatigue. Its robust construction and ergonomic form make it particularly well-suited for high-volume applications where both durability and accuracy are essential.

The scanner’s versatility extends across multiple sectors—from aerospace and automotive to mold casting and digital archiving. Whether it’s capturing the fine geometry of a metallic component, documenting intricate artistic sculptures, or inspecting the surface quality of complex assemblies, Trackit adapts seamlessly to a wide range of scanning scenarios with consistently high-fidelity results.

Public Debut at TCT Detroit

Revopoint officially unveiled Trackit at the TCT Exhibition in Detroit (Booth #2737) from April 8–10, offering live demonstrations of its marker-free scanning capabilities. Attendees can explore how Trackit transforms 3D scanning workflows in real time.

Early Bird Access via Kickstarter

To celebrate the launch, Revopoint is offering a 35% discount for Super Early Bird backers. A $100 deposit secures access to VIP benefits, including free air shipping, priority delivery, and a three-year warranty.

Sign up now to secure the discount and be among the first to experience Trackit’s next-generation 3D scanning technology.