In this article, we review the Prusa XL, Prusa Research’s entry into multi-material, large-format 3D printing. Through 170+ hours of intensive testing, our engineering team assessed how this offering stacks up against its competitors in the desktop FFF market.

Featuring a CoreXY configuration, the 360 mm³ Prusa XL stands out thanks to its tool changer with five independent toolheads, which minimizes waste compared to single-nozzle alternatives and offers a lot more versatility. Boasting a maximum 400 mm/s 3D print speed, Prusa’s large-format system may not sound like the fastest desktop FFF 3D printer. However, its ability to quickly switch between tool heads for different nozzle sizes or filament types enhances productivity for muti-material parts.

Ideal for prototyping and engineering applications, the system also offers straightforward operation, ensuring accessibility for newcomers targeting advanced, large-scale production. Thanks to its robust design, impressive accuracy, and toolhead-switching capabilities, Prusa’s XL is a solid choice for professionals targeting demanding applications. Prices for the fully assembled 3D printer start at €2,599 on the official Prusa website, with the semi-assembled version available for €2,099.

Why choose the Prusa XL?

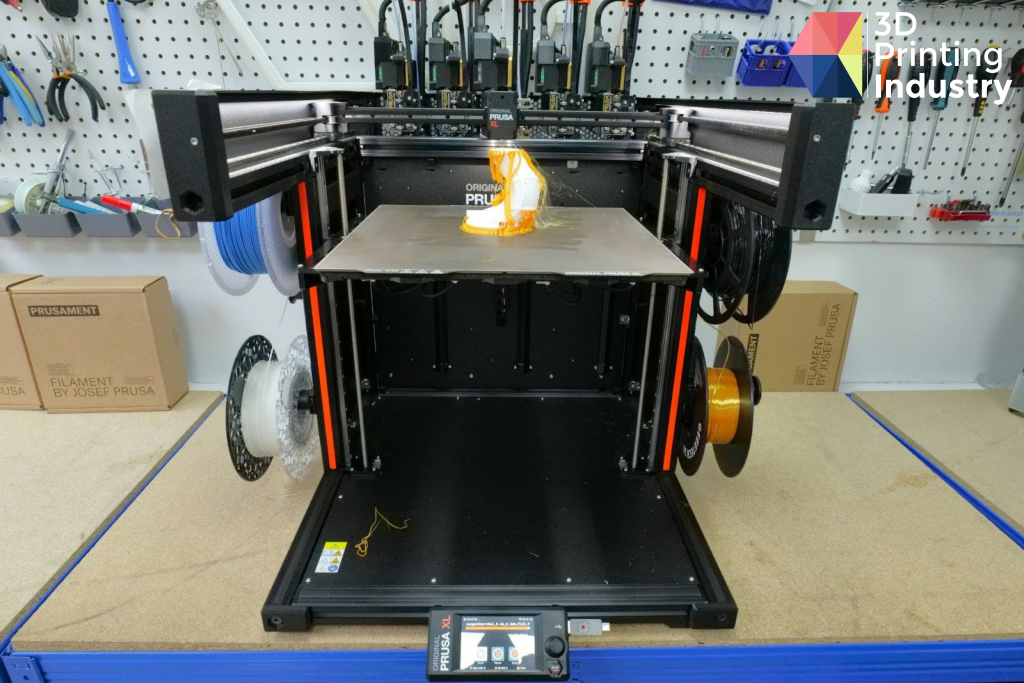

The Prusa XL boasts a substantial build volume of 360 x 360 x 360 mm. This increased capacity unlocks more application possibilities, including large prediction runs, full-sized prototypes, and end-use parts. Given this capacity, it will not be surprising to learn that the printer itself is large, weighing 25.3 kg with 700 x 900 x 720 mm dimensions. Despite this, the XL still fits on the desktop, comfortably integrating into most workspaces.

A key selling point of the 3D printer is its multi-material, five-toolhead setup, which marks a change from Prusa’s single-extrusion product range. Users can load up to five 2kg spools at a time, and the XL can 3D print a 10 kg object without manual interference.

With speedy toolhead-swapping, users can load multiple materials and combine them into a single print job. Flexible filaments can be combined with more sturdy polymers to create functional parts, while more expensive materials can be combined with cheaper support options to lower costs and minimize waste. Different colors can also be integrated into print jobs for enhanced customization and design freedom.

A look around the Prusa XL. Photos by 3D Printing Industry.

A major drawback of most single-extrusion, multi-material systems is plastic waste. These systems typically purge filament when switching materials to clear traces from the nozzle. The Prusa XL overcomes this drawback by allocating each filament with its own toolhead. Purge-free functionality also speeds up multi-material 3D printing, reducing the downtime between material changes.

The Prusa XL’s open design is compatible with most standard 3D printing materials like PLA and PETG. However, for more challenging, sensitive filaments like ASA, ABS, and PA, Prusa offers a dedicated 3D printer enclosure. This add-on provides a stable environment with greater temperature control to prevent defeats and improve part quality.

According to Prusa Research, the print profiles have been tuned to allow users to design precise parts and achieve 0.2mm accuracy. The XL’s sturdy frame and tracking sensors ensure the reliable production of detailed parts. Additionally, its CoreXY motion system unlocks increased precision and speed compared to Cartesian alternatives.

The Prusa XL’s five toolhead assembly. Photos by 3D Printing Industry.

For 3D printing newcomers, manual calibration can be an intimidating and frustrating process. The Prusa XL’s loadcell sensor overcomes these challenges by automatically calibrating the nozzle’s starting position.

Efficiency is boosted further by the XL’s segmented heatbed. Powered by a separate electronic board, it features 16 individually controlled tiles to enable consistent heating and minimize deformation. Unused tiles can also be switched off to save energy.

The Prusa XL enhances usability with an intuitive, easy-to-use, full-color LCD touchscreen interface. Its straightforward menus and clear instructions enable even novice users to quickly access G-code previews and print job controls.

The Prusa XL’s toolhead, printbed, build plate, and user interface. Photos by 3D Printing industry.

How good is PrusaSlicer software?

While third-party slicing software, such as Cura, is compatible with the Prusa XL, the 3D printer is optimized for use with the company’s proprietary PrusaSlicer. This open-source platform is constantly being updated with new features and material profiles. Compatible with Windows, Mac, and Linux, the tool stands out thanks to its beginner-friendly interface.

Through PrusaSlicer, users can modify printer settings and parameters, which are color-coded by experience level: green for beginner, orange for normal, and red for expert. Multi-color 3D printing is easily controlled within the software interface. Users can paint their desired hues directly onto their 3D models. More advanced features, such as the paint-on support tool, offer an extra level of customization for experienced makers. All material presets are meticulously fine-tuned and tested to ensure optimal printing performance.

It is worth noting that certain features require specific keyboard shortcuts to access. For instance, adding text to a part involves pressing the “T” key, which generates a customizable text cutout. This isn’t immediately apparent without reading the quick start handbook, making it a potential barrier for less experienced users.

While the manual paint-on material feature is intuitive for entry-level users, it can lead to imprecise results. PrusaSlicer does offer a smart fill tool that automatically detects and fills regions with color. However, its functionality was found to be limited during testing. Therefore, we believe adding a new feature that allows users to precisely select and assign different geometric sections with specified materials would elevate precision. This would be especially valuable for those targeting demanding, professional-grade applications requiring high-quality parts.

PrusaSlicer interface and Prusa XL dashboard. Images by 3D Printing Industry.

The Prusa Connect cloud platform and Prusa mobile app enable remote 3D printing. Users can communicate directly with their machines, adjust print parameters, and monitor progress. Ideal for print farms, Prusa Connect allows simultaneous management of multiple 3D printers, access to live telemetry data, and tracking of material consumption.

Amid growing concerns around data security, many users will be pleased to learn that offline 3D printing is also available with the Prusa XL. The 3D printer can be completely configured without a network connection, with files able to be uploaded directly via a USB stick. Prusa Research emphasizes this point, asserting that it does not collect any information about 3D printers or their surroundings, even when connected to the internet.

PrusaSlicer 3D print settings and parameters. Images by 3D Printing Industry.

Benchmarking the Prusa XL

Our engineering team conducted 170 hours of benchmark and application testing. We started with a multi-material wrist CT scan model, one of the test files included with the printer. This part utilized three toolheads, providing an early opportunity to assess the XL’s tool-changing capabilities. The bone sections were 3D printed using PLA, while TPU was used for the internal tendons to create lifelike flexibility.

The model was successful at the first attempt. Free of defects, it featured clearly defined bones and joints. The efficiency of material changes significantly reduced overall downtime, eliminating material loading and purging delays. Tool changes were flawless, demonstrating a 100% success rate in picking up and parking the extruder heads.

3D printed wrist CT scan. Photos by 3D Printing Industry.

Repeatability is key for users wanting to produce batches of identical parts. To assess the repeatability of the Prusa XL, we 3D printed square, hexagon, and tube models 12 times each. These were then measured and compared against the intended dimensions.

Most capable 3D printers are expected to achieve an average deviation under 0.1 mm and a standard deviation below 0.05 mm. All three models successfully measured below these limits, indicating impressive accuracy and precision.

Repeatability square, hexagon, and tube models. Photos by 3D printing Industry.

The square parts were comfortably below the benchmark, with an average deviation of 0.0836 mm and a standard deviation of 0.0168 mm. Small discrepancies were noted in the hole diameters. This is a common challenge among FFF 3D printers which often over-extrude when producing circles.

Normal distribution and deviations between the measurements and references for the square models. Images by 3D Printing Industry.

The hexagons achieved a 0.0378 mm average deviation and 0.0167 mm standard deviation, again reflecting solid accuracy and precision. Impressively, no bulging occurred at the corners of the hexagons, something which is often seen in competing FFF systems. This confirms that the XL is perfectly calibrated to avoid over-extrusion when fabricating sharp corners.

Normal distribution and deviations between the measurements and references for the hexagon models. Images by 3D Printing Industry.

For the tube model, the average deviation came to 0.0599 mm, while the standard deviation was just 0.017 mm. The dimensions for the cylinder’s external diameter demonstrated exceptional accuracy. However, the same cannot be said for the cylinder height, which fluctuated between 15.053 mm and 15.095 mm, consistently above the 15 mm target.

Normal distribution results for the tube models. Images by 3D Printing Industry.

As previously mentioned, FFF 3D printers often struggle with circles. Can the Prusa XL 3D print a perfect circle? To find out, we produced several test models, each of which featured three circular sections of 100 mm, 65 mm, and 20 mm. A mean of difference below 0.1 mm for both the X and Y axes would be considered a good result. The Prusa XL succeeded, with 0.0211mm for the X-axis and 0.0166mm for the Y-axis.

3D printed circular trajectory tests. Photos by 3D Printing Industry.

A common cause of imperfect 3D-printed circles is that .stl files use triangles to form meshed bodies, often resulting in jagged edges. However, PrusaSlicer’s Arc Fitting tool addresses this by automatically converting sharp segments into smooth arcs. This is a novel feature we have not seen in many 3D printer slicers. Our testing demonstrated its impressive effectiveness, helping the XL stand out in the desktop market. After measuring and comparing all models, the mean standard deviation was 0.0179 mm (well below the 0.05 mm threshold), while the mean of all differences was 0.0188 mm (under our 0.1 mm benchmark).

The normal distribution of the circular trajectory tests. Images by 3D Printing Industry.

We next tested the Prusa XL for ‘capability.’ With its origins in 1970s US automotive manufacturing, this assessment leverages statistical process control to assess whether a 3D printer can reliably mass-produce parts at high volumes.

During the test, we 3D printed a small tubular model 150 times. 16 were then selected at random and measured three times. Using these results, we calculated the process capability, a measure of how well the system can consistently produce parts within specified limits. We also determined the minimum process capability, which accounts for possible decentring.

A score above 2.0 is optimal, while anything below 1.33 is not acceptable. The Prusa XL achieved a process capability of 3.84, well above the target. This confirms the large-format, multi-material 3D printer’s commendable precision, making it well-suited to high-volume production runs. Its minimum process capability score of 2.48 was also impressive, suggesting a low likelihood of part defects. This makes the XL a solid choice for users requiring reliable, repeatable performance.

3D printed capability test parts. Photo and image by 3D Printing Industry.

The Prusa XL’s build volume of 360 x 360 x 360 mm stands out as one of the biggest in the desktop 3D printing market. But how well does the XL handle large-scale parts? To find out, we first 3D printed a slender tower reaching the 3D printer’s maximum advertised height. We expected a good result here, given that CoreXY configurations minimize vibrations, ensuring greater stability during production.

The 360 mm Z-axis was achieved effortlessly, confirming the maximum height dimensions of the Prusa XL. A smooth surface finish and excellent layer consistency characterized the tower, a testament to the 3D printer’s robust frame and vibration compensation capabilities.

Our perimeter test confirmed that the 360 x 360 mm X/Y axes can also be fully utilized. The part exhibited a defect-free surface, with perfect first and last layers, indicating an optimal extrusion rate. The Prusa XL is certainly a great choice for those wanting to produce large-scale parts on the desktop.

3D printed perimeter test. Photo and image by 3D Printing Industry.

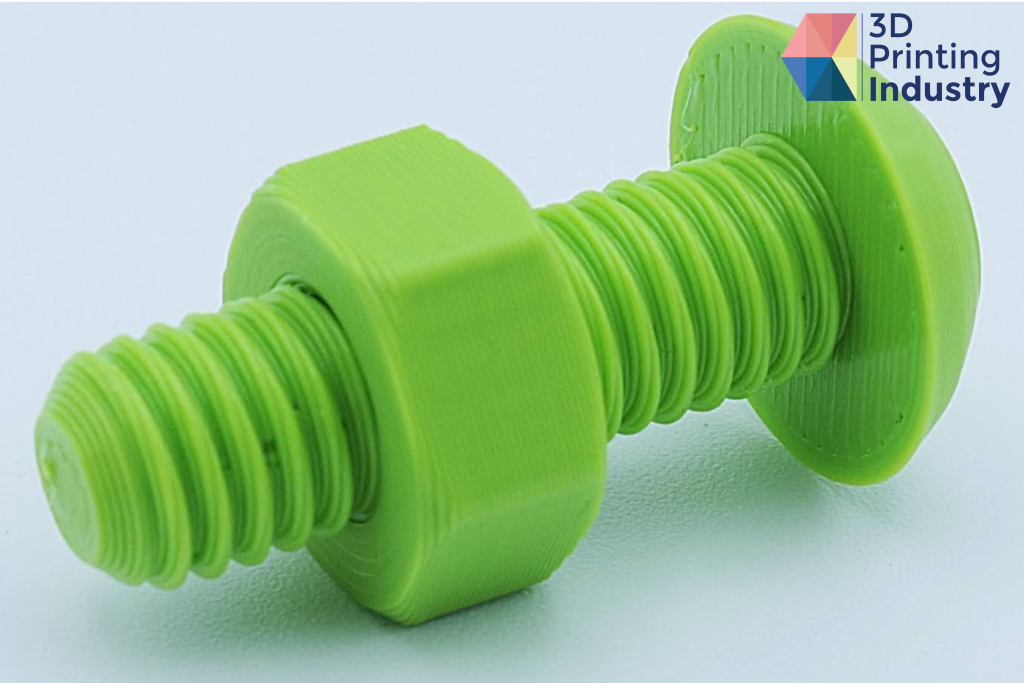

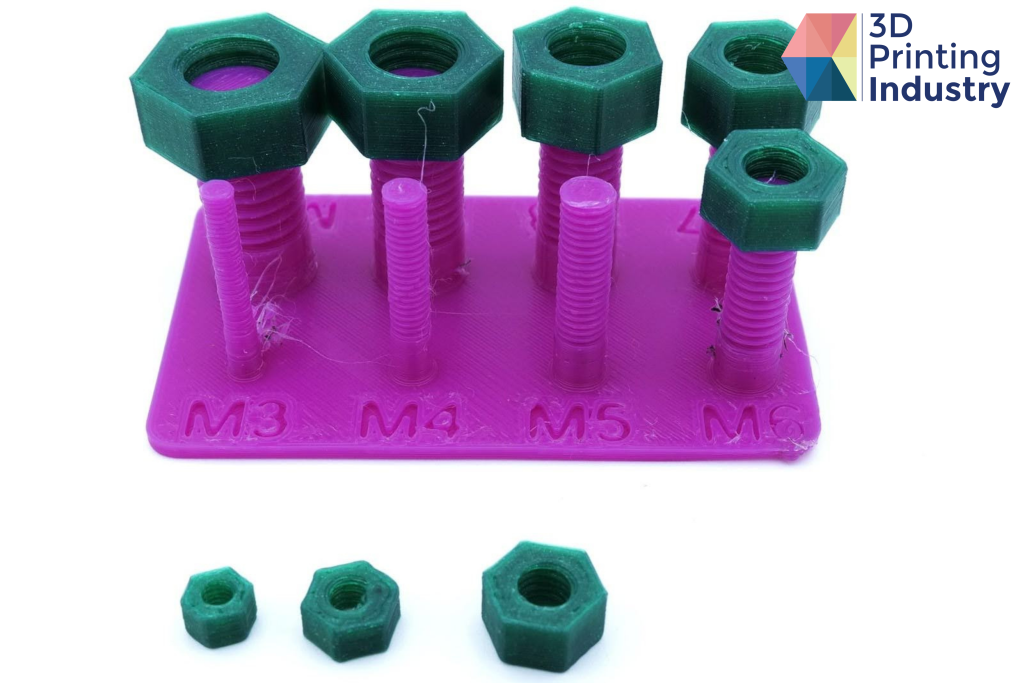

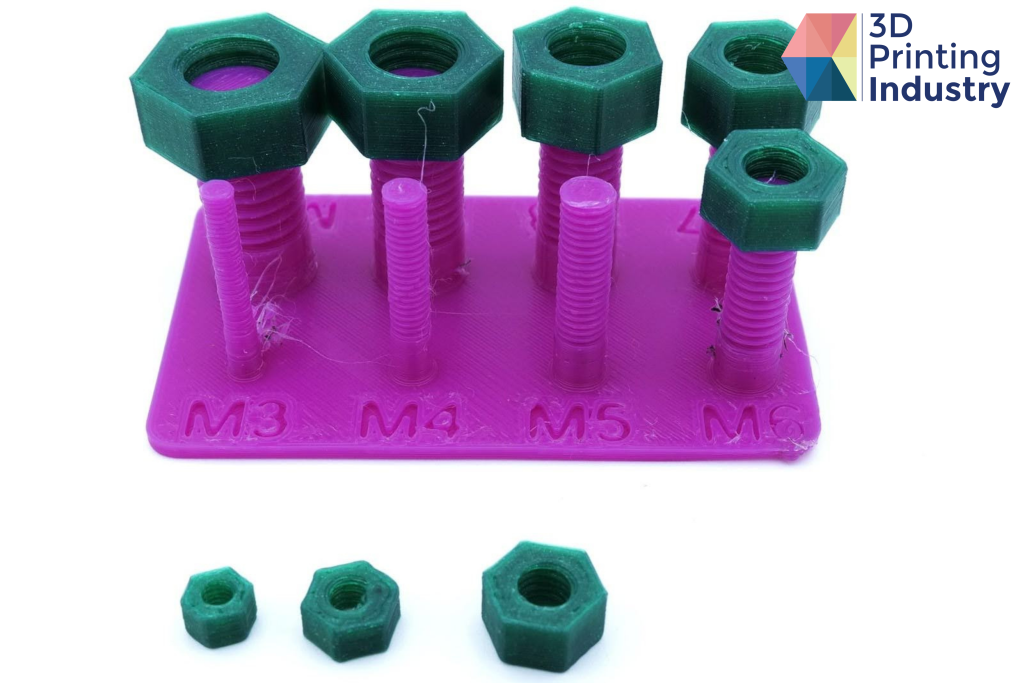

While the XL is optimized for sizeable parts, our next test determined how well it can handle smaller, more precise components. We 3D printed a functional nut and bolt model with high tolerances and a 1.25 mm thread pitch. The model was fully functional and reproduced all intricate details to a high standard.

Following this, we upped the difficulty with eight threads ranging from an M10 1.5 mm thread pitch to an M3 0.5 mm thread pitch. The XL produced accurate, functional models from M10 to M6 (1.0 mm), failing at M5 (0.8 mm). This is above average for the desktop FFF market, with most competing 3D printers only able to reach a 1.25 mm thread pitch.

Next, we 3D printed our in-house 3D Printing Industry benchmarking test. This model features a range of challenging geometries designed to push the 3D printer to its limits.

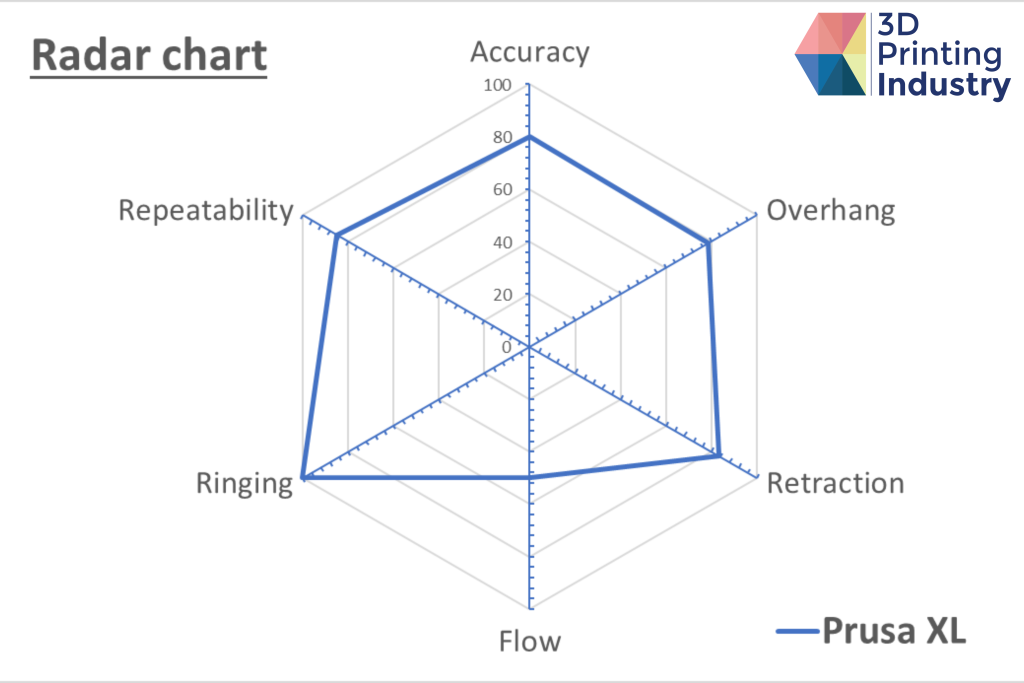

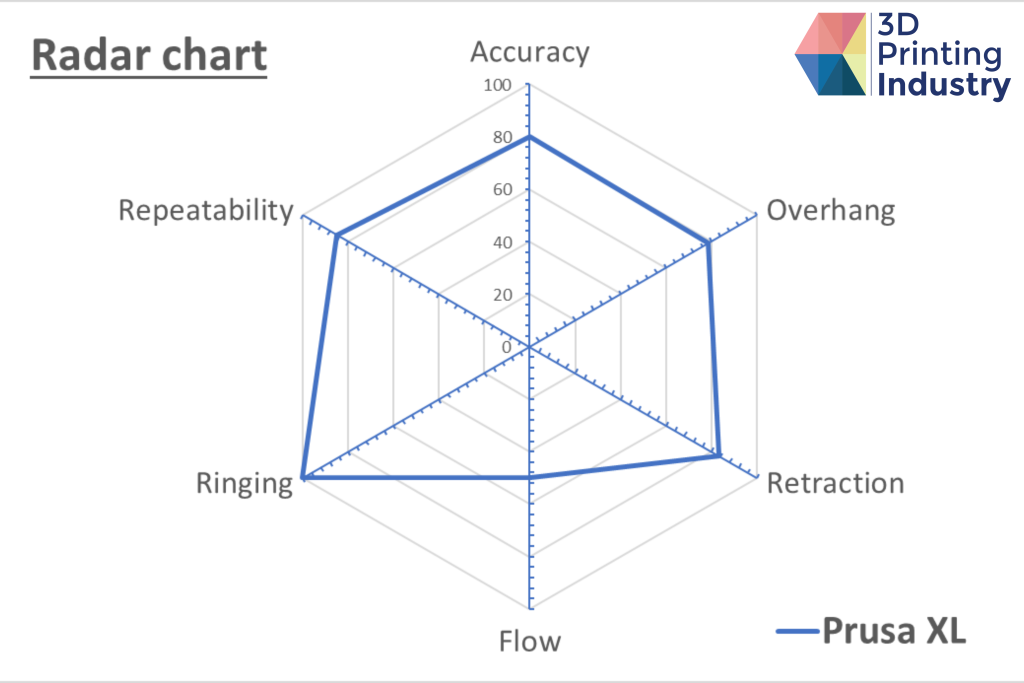

The Prusa XL achieved a commendable, above-average score of 82.47. Large-format systems tend to struggle with high vibrations caused by their larger momentum. However, the XL’s input shaper configuration minimized these challenges. This was confirmed by the model’s lack of defects like ringing and stringing.

Prusa XL 3DPI test. Photos by 3D Printing Industry.

The repeatability section performed especially well, ranking second among all 3D printers we have tested. Solid results for retraction, overhang, and accuracy were also noted. For overhangs, in particular, the XL produced successful results up to the 75° angle, significantly higher than the 50° average of most competing models.

Minor issues were experienced in the flow sections of the test, with the final three negative precision cylinders, unfortunately, fusing to the main body. This was caused by PrusaSlicer failing to detect thin gaps of 0.1 to 0.2 mm.

Testing Prusa XL applications

Next, our team assessed how well the Prusa XL is suited to real-world applications. Beginning with a medical theme, we 3D printed an anatomical heart model using four toolheads to highlight cardiovascular features. Completed in 33 hours, the model showcased impressive detail and accuracy, with minimal defects and no color bleeding. This is a strong demonstration of the Prusa XL’s multi-material capabilities, enabling a level of color-based freedom unattainable with mono-material systems.

3D printed anatomic heart model. Photos by 3D Printing Industry.

We also produced an induction tube with a TPU body and PLA supports. This part was downscaled to 70% for time purposes, though it still took 12 hours to complete. The Prusa XL is fairly slow, given that the standard print settings are set to 80 mm/s on the perimeters and 120 mm/s for the infill. This is necessary to help minimize the vibrations caused by its significant momentum.

We attempted to print the model three times, with nozzle clogging being a recurring issue. Four false clog readings disrupted the process, indicating over-sensitivity in the XL’s extruders. However, on our final attempt, we successfully produced a high-quality part. The functional prototype demonstrated excellent consistency, with no visible gaps and precise, defect-free mounting points. Minor stringing was present but is typical for TPU, a hygroscopic material prone to moisture absorption.

A steering rack boot is a critical component in automotive manufacturing. It is a flexible cover that fits over the end of a car’s steering rack, protecting internal components from dirt. With a TPU body and PLA support, our 3D printed steering boot cover features a perfect surface finish. While not able to prevent leakage completely, it would serve as an effective cover, shielding internal hardware. This part is certainly a good prototype, making the XL a solid choice for iterating automotive design improvements.

3D printed steering boot cover. Photos by 3D Printing Industry.

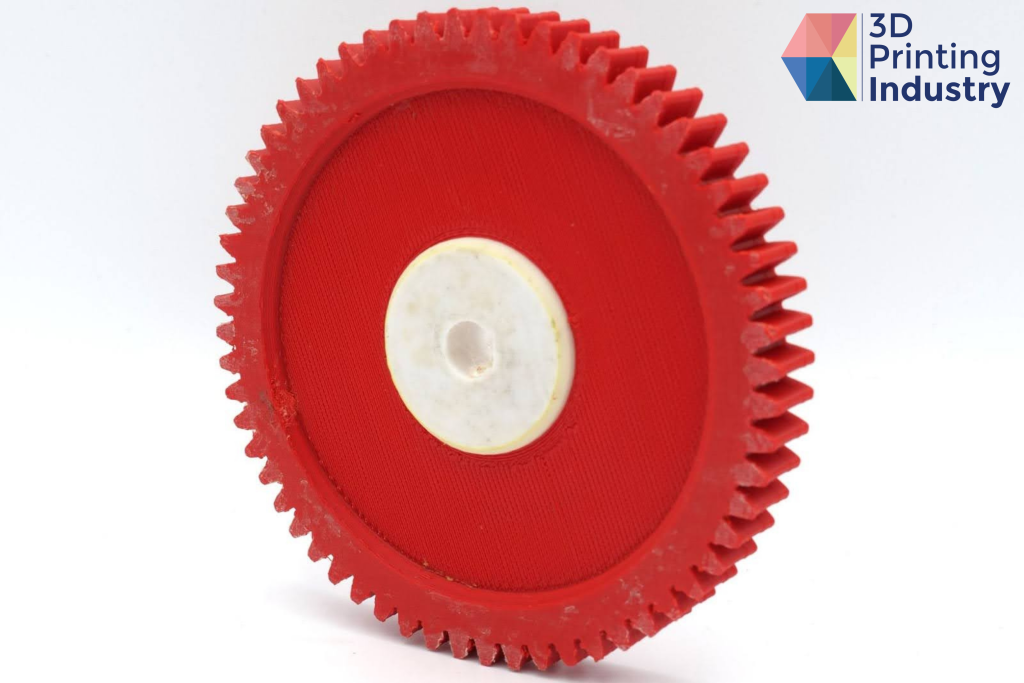

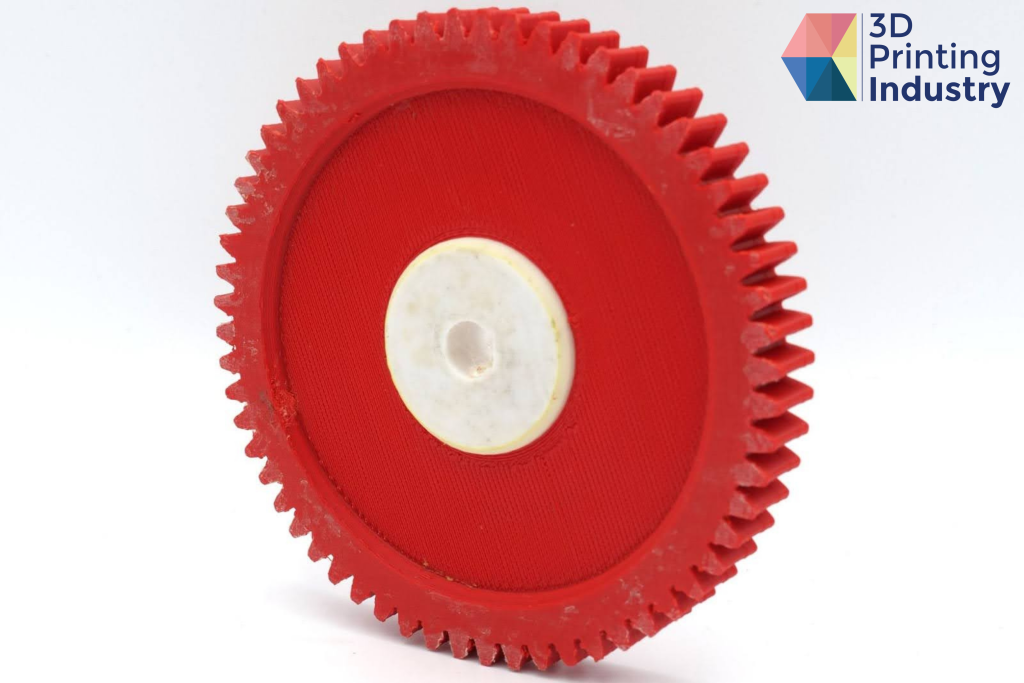

We next sought to combine three materials into a gear component. While PA is generally used for gears due to its wear-resistant properties, the core can become compromised due to the heavy axial load. Therefore, we chose a more rigid PC filament for this section, with a PETG support material

Four attempts were made in this test. All failed due to poor bed adhesion with PA. This caused significant warping, completely deforming the gear’s teeth. We found PA prints to be virtually impossible with Prusa XL’s open architecture and satin aluminum sheet. However, better results would be possible by adding Prusa’s enclosed build environment and a specialized nylon sheet.

Multi-material gear 3D printed with PC and PA. Photo by 3D Printing Industry.

After replacing PA with ASA, we produced a much-improved gear component, with impressive precision and a defect-free finish ensuring functionality. This success highlights the XL’s ability to process ASA, a material that typically presents challenges with warping.

Generative design is a growing trend within design and engineering applications. It offers the ability to better optimize components for specific criteria like strength and heat dissipation. These designs often create incredibly complex geometries, posing challenges for conventional manufacturing methods.

To determine whether the Prusa XL can capitalize on this growing demand, our team 3D printed a generatively designed automotive bracket. We 3D printed two test models. One included a purge tower to ensure the nozzle was completely clean between changes. This generated more material waste but resulted in a better-quality part with fewer defects. It featured the structural integrity required for functional prototyping, representing a successful result for the XL. On the other hand, the part made without a purge tower exhibited several defects caused by collapsed support branches which became trapped between layers.

3D printed generative design bracket made with (first image) and without a purge tower. Photos by 3D Printing Industry.

Lastly, we 3D printed a 3D print a motorcycle triple tree clamp prototype using four materials: PETG, PC, TPU, and ASA. This combination unlocks more valuable parts with improved functionality. Rigid materials like PC can reinforce internal structures, while TPU adds shock-absorbing regions.

The triple tree clamp was completed successfully, with optimal layer adhesion and no noticeable defects. This validates the ability of the Prusa XL to 3D print accurate multi-material parts without mechanical errors, making the system a great option for advanced prototyping applications.

3D printed triple tree clamp. Photos by 3D Printing Industry.

Large-format, multi-material 3D printing with the Prusa XL

The Prusa XL is a standout addition to the desktop FFF 3D printer market, offering a unique combination of toolchanging-powered multi-material printing and an extra-large build volume. Designed for engineering, design, and manufacturing applications, it features sturdy construction, an intuitive user interface, and seamless integration with the Prusa ecosystem, making high-performance 3D printing more accessible.

Equipped with five independent toolheads, the Prusa XL enables multi-material and multi-color printing with minimal waste. This capability enhances versatility but can also increase print times, especially when using more than two filaments. In our testing, we successfully combined complex materials to create functional, high-quality parts. While the PrusaSlicer’s existing paint-on multi-material interface is intuitive and accessible to newcomers, the addition of a more refined and granular control system would unlock greater precision for more demanding applications.

Our repeatability tests confirmed the 3D printer’s ability to consistently produce highly accurate and precise parts. The mean dimensional difference across all test prints was 0.0501 mm (well within the 0.1 mm threshold), and the mean total standard deviation measured 0.0171 mm (below the 0.05 mm limit). The CoreXY architecture further enhances reliability, making the XL ideal for applications requiring tight tolerances, such as engineering prototypes and intricate design models. Despite its large build volume, the 3D printer also excels at producing small, detailed parts.

However, we encountered some challenges during our extensive testing. The filament sensing system proved unreliable, frequently triggering false clogging alerts that led to unnecessary stoppages. Additionally, the XL lacks print failure detection sensors, which can result in failed prints and wasted material.

Despite these drawbacks, the Prusa XL impresses with its versatility, multi-material capabilities, and large build volume. It offers great design freedom, minimal material waste, and a competitive price point, making it an excellent choice for both beginners and professionals.

Technical specification of the Prusa XL

| 3D Printing Technology | FFF (Fused Filament Fabrication) |

| Build Volume | 360 x 360 x 360 mm |

| Toolhead Capacity | Five |

| 3D Printer Kinematics | Core XY |

| Max Hotend/Heatbed Temp. | 290°C / 120°C |

| Layer Thickness | 0.05 – 0.30 mm |

| 3D Printing Speed | Up to 400 mm/s |

| Nozzle Provided | Prusa Nozzle Brass 0.4 mm |

| Stepper Drivers | Trinamic 2130 |

| 3D Printer Dimensions | 700 x 900 x 720 mm |

| 3D Printer Weigh | 25.3 kg |

| Wi-Fi module | Built-in; network connectivity is not required for setup or operation |

| File output | .gcode |

Who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on X, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows the Prusa XL. Photo by 3D Printing Industry.