Metal 3D printer manufacturer Nikon SLM Solutions has formed a strategic partnership with U.S.-based specialty materials producer Allegheny Technologies Incorporated (ATI) and engineering firm Bechtel Plant Machinery, Inc. (BPMI) to drive advancements in hypersonic and naval propulsion technologies. As part of this collaboration, ATI has acquired the NXG 600E metal additive manufacturing system to boost production capacity for critical components supporting U.S. Navy and Department of Defense programs at its manufacturing sites.

“The NXG 600E’s expansive build volume and sophisticated support structure capabilities align seamlessly with U.S. Navy propulsion requirements,” expressed Nathan Weiderspahn, BPMI Executive Manager, Industrial Base Management. “Nikon SLM Solutions’ cutting-edge additive manufacturing technology is set to play a pivotal role in advancing the U.S. Navy’s operational readiness, contributing to the maintenance and enhancement of our nation’s fleet.”

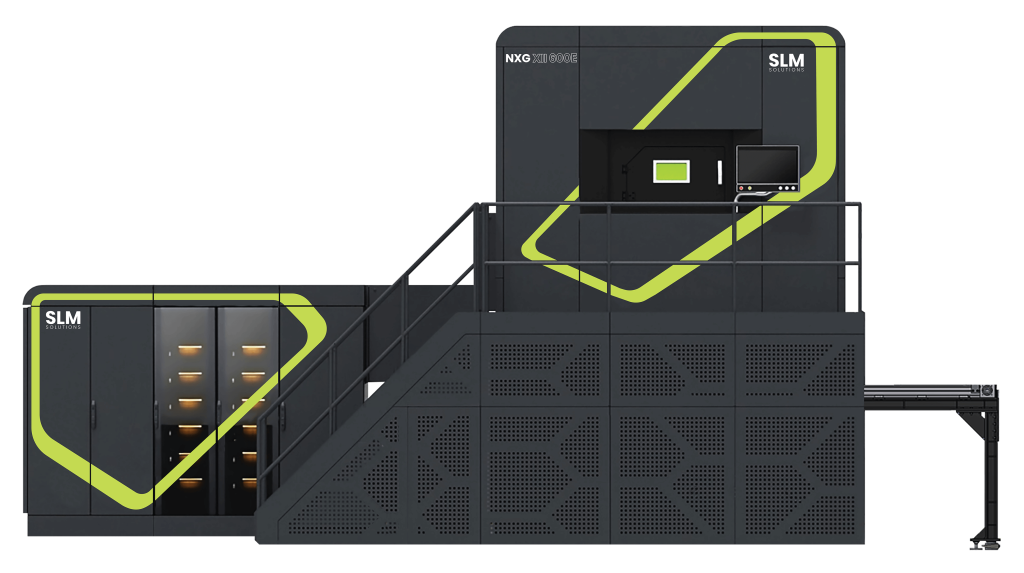

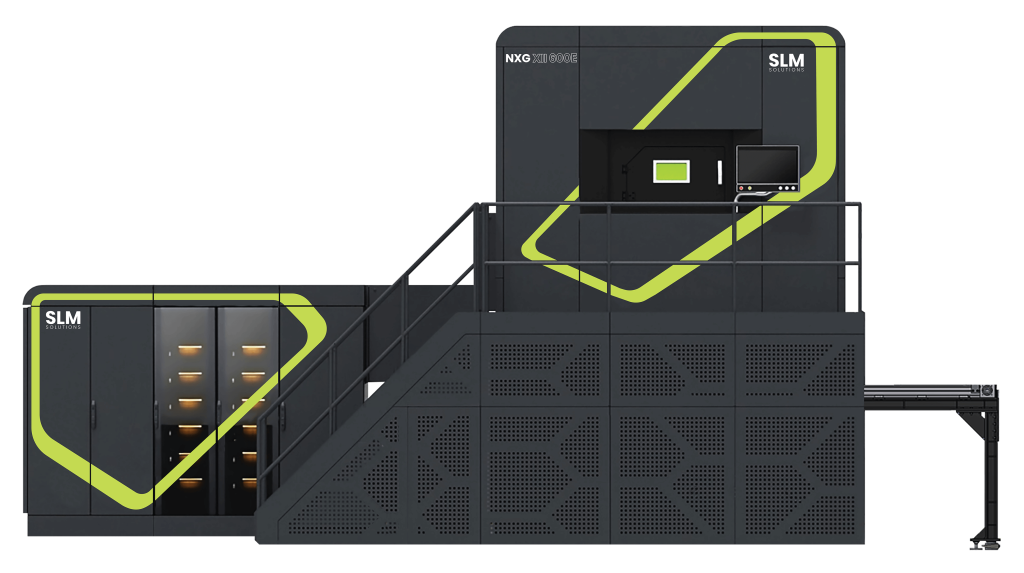

Expanding Defense Manufacturing with the NXG 600E

As part of this partnership, ATI has purchased the NXG 600E metal additive manufacturing system. The system was selected to address the technical requirements of U.S. Navy propulsion and hypersonic weapon components. With its 1.5-meter Z-axis and high production capacity, the NXG 600E is intended to support ATI’s manufacturing capabilities in defense applications.

ATI plans to utilize Inconel 625 with the NXG 600E, a high-performance alloy widely used in hypersonic and naval propulsion systems, as well as various demanding industrial applications. The June delivery of the NXG 600E is expected to enhance ATI’s metal additive manufacturing capabilities, leveraging their proven success with the SLM125 and expertise in Nikon SLM’s open machine architecture and advanced parameter development.

“In the dynamic landscape of additive manufacturing, Nikon SLM Solutions is taking a significant leap forward,” said Sam O’Leary, CEO. ” This strategic development underscores our commitment to delivering American-made ingenuity, superior technology, and empowering the defense and aerospace sectors with cutting-edge additive manufacturing capabilities,” said Sam O’Leary, CEO of Nikon SLM Solutions.

Industrial Adoption of the NXG XII 600E

Launched in 2022, the NXG XII 600E by SLM Solutions is a metal additive manufacturing system with a build volume of 600 × 600 × 1,500 mm enabled by a 1.5-meter Z-axis. Equipped with twelve 1,000-watt lasers, the NXG delivers fast and accurate melting of metal powder, enabling the production of high-quality, uniform parts. The system is designed to handle large, complex components in a single build and supports industrial-scale production with features aimed at improving speed and process control. It includes workflow enhancements intended to maximize machine uptime and reduce production cycle times.

Among the recent adopters of the NXG XII 600 technology is German multinational engineering and technology company Bosch launched a new metal additive manufacturing facility at its Nuremberg plant, investing nearly €6 million. At the heart of the facility is a Nikon SLM Solutions NXG XII 600 metal 3D printer, which the company says will play a key role in producing complex metal parts more efficiently. With this addition, the automotive giant sees itself as the first Tier-1 automotive supplier in Europe to operate a facility in this performance class.

Elsewhere, semiconductor manufacturing company Veeco started using Nikon SLM Solutions’ NXG XII 600 metal AM system to advance its production processes. Designed for creating intricate components such as gas delivery systems and heat exchangers, the technology enhances precision and efficiency in semiconductor manufacturing. Having integrated additive manufacturing into its operations, Veeco aims to enhance productivity and accelerate time-to-market.

Take the 3DPI Reader Survey — shape the future of AM reporting in under 5 minutes.

Who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows Nikon 3D Printing. Photo via Nikon.