Ceramics 3D printing OEM and process provider 3DCeram has introduced CERIA, an advanced artificial intelligence (AI) tool crafted to elevate ceramic 3D printing processes, enhancing efficiency, reducing costs, and improving precision across industrial applications.

Tailored for 3DCeram’s Ceramaker range, CERIA is built to meet the rigorous requirements of industries like aerospace, defense, and semiconductors, which demand high-resolution ceramic parts that maintain integrity at a large scale, challenges that CERIA is designed to overcome.

Visitors at Formnext tradeshow this week can explore CERIA’s capabilities at 3DCeram’s booth in Hall 11.1 D21. The demonstration will highlight CERIA’s potential to reshape ceramic additive manufacturing for high-performance, technical applications.

Modular AI system to streamline production

Structured around two core AI modules, CERIA provides a comprehensive solution to streamline the entire 3D printing workflow. CERIA Set customizes printing parameters for each project, analyzing part designs and generating configurations that maximize productivity and precision.

Meanwhile, CERIA Live delivers real-time monitoring and adjustments, maintaining an uninterrupted production flow. Together, these modules harness the benefits of stereolithography, enabling large-scale, automated production that suits the industrial scale and intricate demands of technical ceramics.

According to the company, CERIA also integrates seamlessly with 3DCeram’s existing tools, Build-It and CPS 2.0, forming a complete ecosystem for managing every stage of ceramic 3D printing. CERIA Set provides targeted support from conception to production, guiding users in optimizing part placement and tank layout, and generating custom scraping parameters that meet exacting standards.

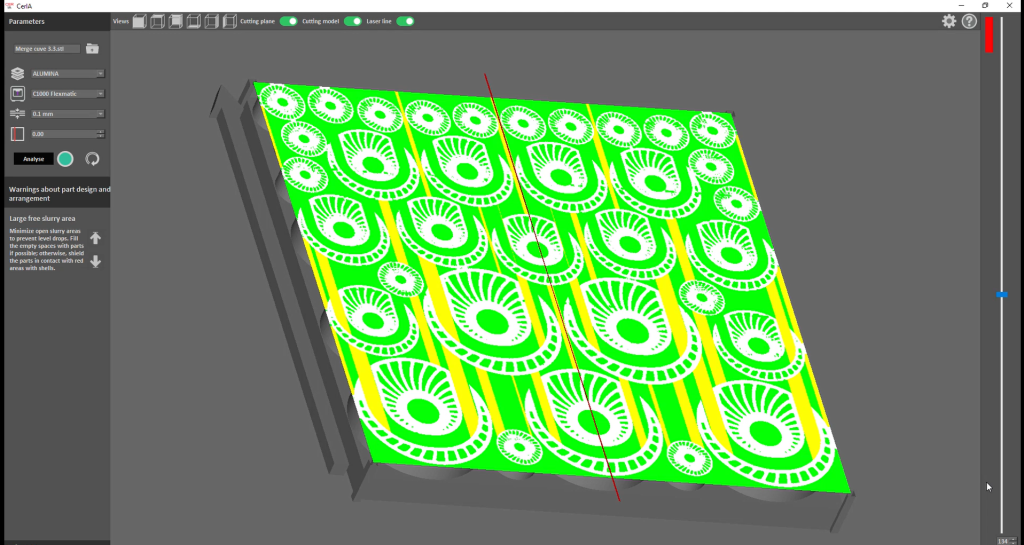

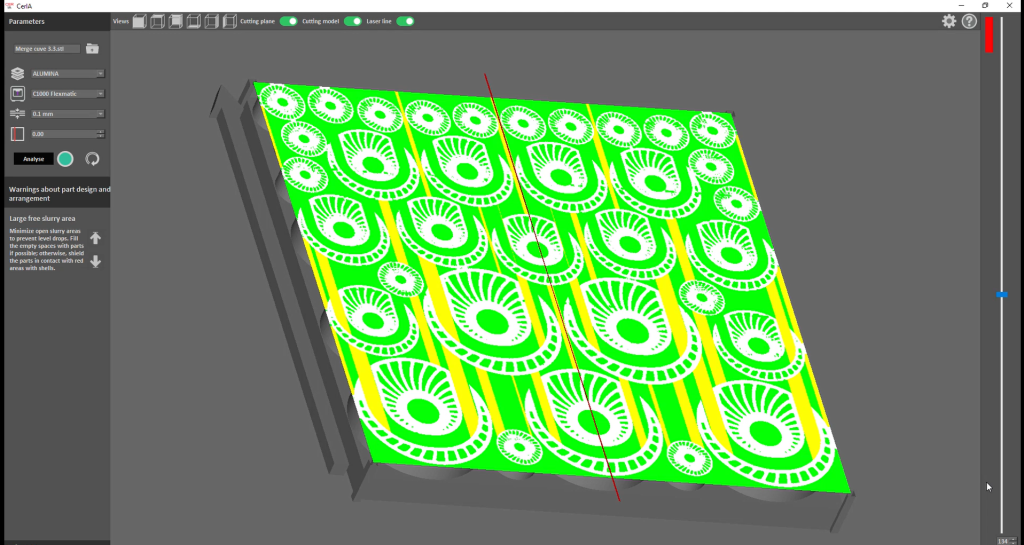

By including a color-coded visualization system, CERIA Live enables real-time monitoring of each layer during the print process. Each color serves a purpose: white highlights the part being printed, yellow signals fixed slurry zones, and red marks potential slurry leaks, helping users identify and address issues quickly to ensure production success.

Versatile applications across technical ceramics manufacturing

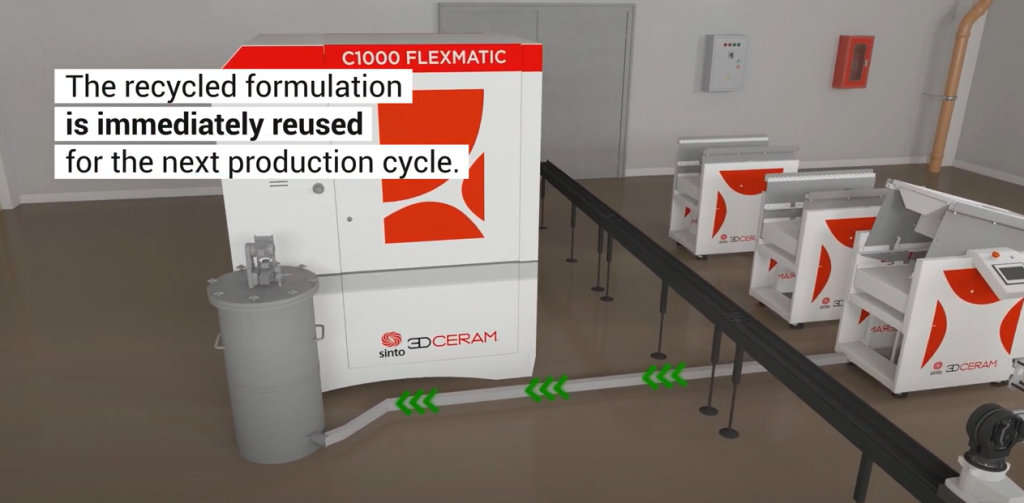

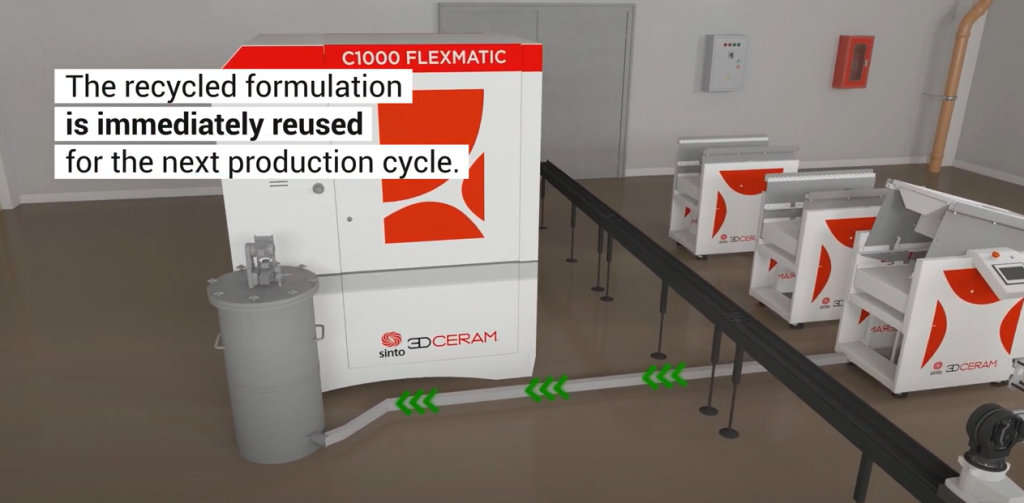

Compatible with high-precision models like the C101 EASY FAB, C1000 FLEXMATIC, and C3601 ULTIMATE, CERIA’s adaptability extends to a wide range of technical ceramics applications.

This versatility allows manufacturers to minimize material waste, reduce time to market, and achieve consistent, high-quality results. Efficiency is particularly crucial for technical ceramics, where streamlined production can make or break the ability to meet tight deadlines in industries like aerospace and semiconductors. A large build platform enhances this by allowing large parts to be printed as a single piece.

With over 20 years of experience in ceramic 3D printing, CERIA underscores 3DCeram’s focus on refining AM for complex applications. Equipped with AI-driven design guidance, an emphasis on material efficiency, and real-time monitoring, CERIA provides a scalable solution aimed at enhancing the capabilities of ceramic 3D printing.

As manufacturers look for dependable and cost-effective production methods, CERIA aims to contribute to the broader adoption of ceramic 3D printing across various industries.

Catch up on all the news from Formnext 2024.

Voting is now open for the 2024 3D Printing Industry Awards.

Want to share insights on key industry trends and the future of 3D printing? Register now to be included in the 2025 3D Printing Industry Executive Survey.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows CERIA’s color-coded visualization optimizes part placement and detects slurry issues in 3D printing. Image via 3DCeram.