Australian large-format 3D printer manufacturer AML3D Limited has announced a A$0.83 million contract with British aerospace firm BAE Systems for the supply of 8.5 tonnes of Nickel Aluminium Bronze (NAB) wire feedstock. This contract marks a step in AML3D’s efforts to expand its manufacturing capabilities in Australia and support defence programs in both the U.K. and Australia. It also follows the opening of the company’s U.S. facility in December 2024.

“AML3D has been developing its relationship with BAE Systems for over a year. It is very exciting to see that work translate into an initial contract from BAE Systems. It is even more exciting that this contract is planned to be just the first and I look forward to giving updates on additional contracts as the program progresses,” said CEO Sean Ebert.

Ebert noted that AML3D is entering the next phase of its growth strategy by leveraging demand from the U.S. Navy’s Submarine Industrial Base to expand into allied defence markets. Alongside the BAE Systems contract, the company is exploring further opportunities with other U.K.-based defence partners. “While winning Defence contracts can take time, I am confident that we will be in a position to announce additional orders from the U.K. and Australian defence sectors to compliment the huge momentum we are seeing in the U.S.,” he added.

Broader growth through defence and industrial contracts

The BAE Systems agreement comes amid broader efforts by AML3D to scale operations through strategic defence and industrial engagements. In the first half of 2024, approximately 80% of AML3D’s sales were generated from U.S.-based customers, reflecting a growing footprint in that market.

To meet increasing demand, the company launched a U.S. Technology Centre and secured a A$2.27 million contract with the Tennessee Valley Authority (TVA) to deliver 3D printed components for critical power generation infrastructure.

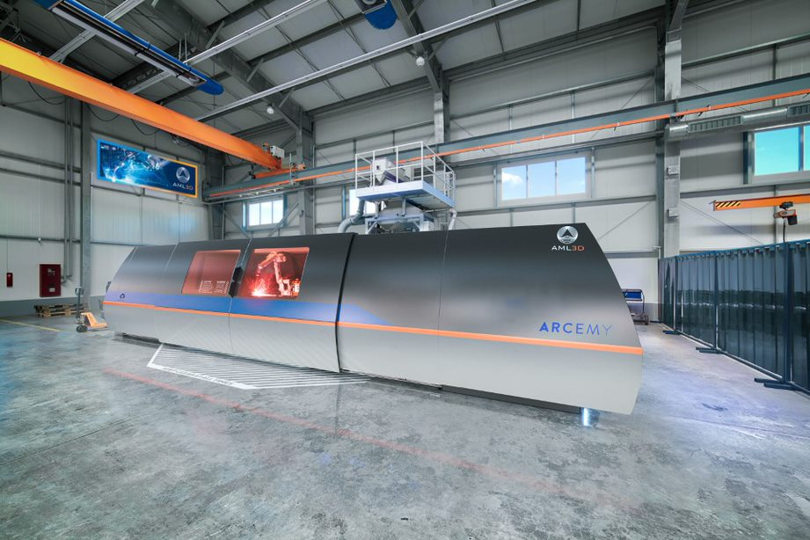

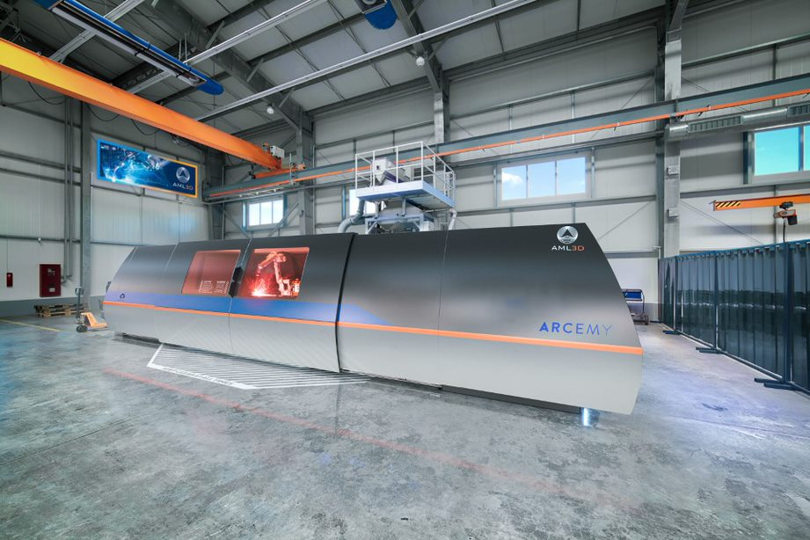

Defence remained a central area of focus during the period. AML3D entered a Manufacturing License Agreement with BlueForge Alliance to support the U.S. Navy’s submarine program and delivered ARCEMY systems to key suppliers including Laser Welding Solutions and Cogitic Corporation—supporting efforts to address supply chain constraints within the U.S. Department of Defense.

In support of its long-term plans, AML3D completed a $30 million institutional placement in December 2024. The funds will be used to scale U.S. operations, establish a European Technology Centre to serve the U.K. defence market, and invest in research and development.

In January 2025, the company delivered prototype tailpiece components—3D printed in Copper-Nickel alloy—for the Virginia-Class nuclear submarine program under the AUKUS partnership. Valued at approximately A$156,000, the parts will undergo testing prior to installation on a Virginia-Class submarine. According to AML3D, the components were produced in under five weeks, compared to a 17-month lead time using conventional manufacturing methods.

Who won the 2024 3D Printing Industry Awards?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on LinkedIn, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows AML3D ARCEMY metal 3D printer. Photo via: AML3D.