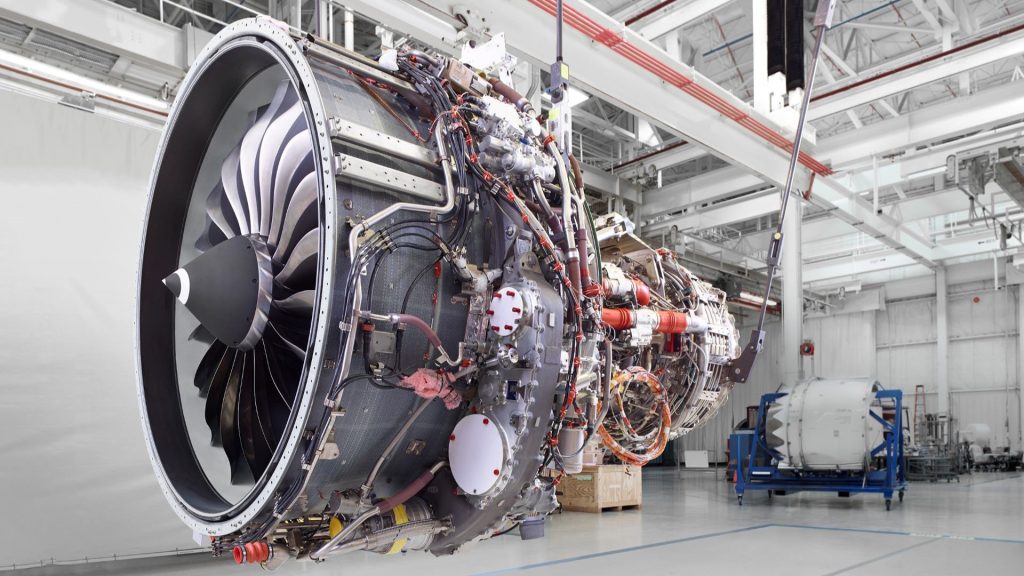

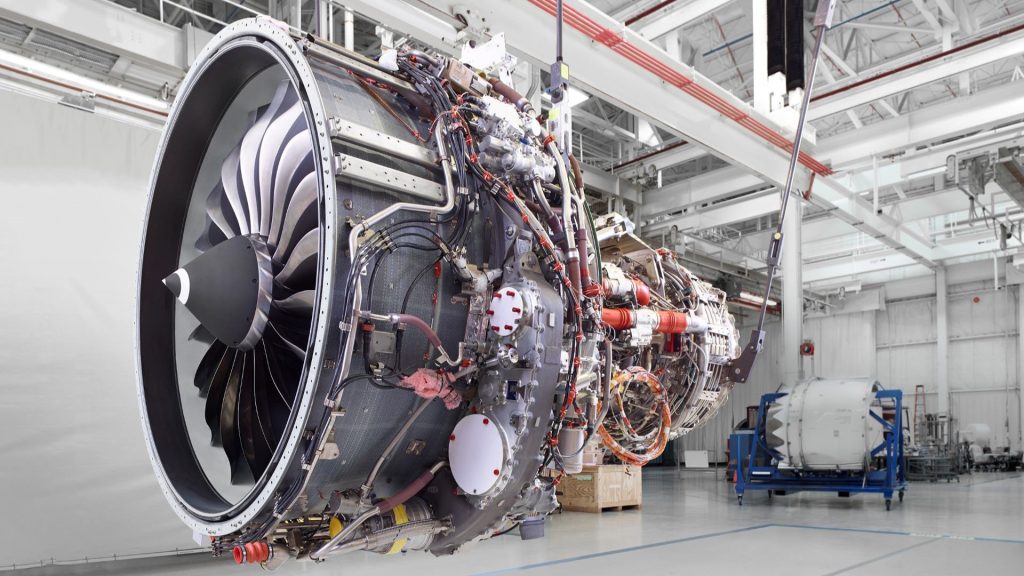

Aerospace manufacturer GE Aerospace has reported its financial result for Q3 2024, posting 6% revenue growth amid a 28% increase in orders. Notably, the company is experiencing strong demand for its aircraft jet engines, particularly the 3D printing-enabled CFM LEAP engine.

Featuring GE’s landmark 3D printed fuel nozzles, LEAP engines are developed by CFM International, a joint venture with French aerospace manufacturer Safran. They power the Airbus A320neo, Boeing 737 MAX, and COMAC C919 aircraft.

Q3 2024 saw aviation finance firm Avolon order 150 LEAP-1A engines for 75 A320 aircraft. This adds to the growing LEAP engine backlog, which reportedly exceeded 10,000 in July 2024. GE Aviation’s total order backlog amounted to a substantial $149 billion in Q3 2024, with 90% of this reportedly linked to its services segment.

To address this demand, GE Aerospace invested over $650 million into its global production capacity and supply chain earlier this year. This was followed by an additional $1 billion investment for its global Maintenance, Repair and Overhaul (MRO) and component repair facilities.

However, according to a recent investor earnings call, supply chain issues contributed to a 4% YoY decline in total engine deliveries in Q3, with LEAP deliveries falling 6%.

The engine manufacturer remains confident in its ability to address this demand. Despite the YoY decline, engine deliveries reportedly increased by over 20% sequentially. Additionally, LEAP’s fleet size is projected to double by 2030, with the company expanding capacity to support aftermarket growth. GE Aerospace grew LEAP internal shop visits (full engine inspections and repairs) by more than 20% YoY. It will also add a new dedicated LEAP MRO shop in Poland to its internal network.

“We know we’ve got an incredible backlog here,” stated GE Aerospace’s CEO Lawrence Culp during a Q&A session with investors. He added that “LEAP will be down, unfortunately, year-over-year in terms of new engine deliveries. But I think we’re poised […] to deliver good growth going into 2025. That’s the goal.”

GE Aerospace’s Q3 2024 results

After becoming an independent public company earlier this year, GE Aerospace has reported positive results for the third financial quarter of 2024.

The company generated $9.8BN in revenue, representing a 6% increase compared to $9.3BN in Q3 2023. Driving this increase was $12.6BN worth of orders, up 28% YoY, amid growth in its services and equipment segments. GE Aerospace’s Q3 2024 operating profit reached $1.8BN, a 14% increase YoY from $1.6BN. The profit margin was 19.2%, up 1,560 basis points from 3.6% in Q3 2023.

Adjusted earnings per share (EPS) came to $1.15, up 25% YoY, while cash from operating activities grew 7% to $1.9BN. GE Aerospace’s $1.8BN in free cash flow represented a 5% increase compared to the $1.7BN reported a year prior. A $328M pre-tax charge connected to an agreement to settle a legacy shareholder lawsuit was also recorded in Q3.

During the quarter, GE Aerospace performed an interim impairment test at Colibrium Additive following ‘declines in the additive manufacturing industry.’ Q3 2024 reportedly witnessed slower adoption of 3D printing technology, resulting in a non-cash loss of $251M in Goodwill.

Despite this drop, GE Aerospace affirmed that Colibrium remains critical to its business operations, particularly concerning its 3D printing-enabled LEAP and 9X engines. “It will be a key enabler for a future of flight as we continue to focus on where it can create the most value,” explained Chief Financial Officer Rahul Ghai during the Q3 2024 earnings call.

The company claims that its ‘strong year-to-date performance’ and positive trajectory entering Q4 2024 justifies its decision to increase its full-year 2024 guidance. It is anticipating high single-digit growth for total adjusted revenues, with operating profit set to reach between $6.7 (+20% YoY) and $6.9BN (+23% YoY).

Addressing the LEAP engine backlog

GE Aerospace engine demand continued to grow in Q3 2024. Commercial Engines and Services (CES) saw orders increase 29% YoY, with over 20% growth in services and equipment. LEAP’s share of global narrowbody aircraft departures increased by 20%. However, meeting this “historic demand” has been challenging. Due to supply chain constraints, LEAP engine deliveries fell 6% YoY with 356 units shipped in Q3 2024.

To address this backlog, GE Aerospace has continued to develop its Flight Deck lean operating model announced in April. Designed to cut costs and align operations with customer expectations, Flight Deck is reportedly addressing supply chain constraints at the company’s top 15 supplier sites. For example, Q3 saw over 515 engineers dispatched across several sites, reportedly increasing output rates by 18%.

GE Aerospace also claims to be making progress on increasing the LEAP engine’s time-on-wing (TOW) operational reliability. The company has launched the 1A durability kit, including an upgraded HPT blade, which is expected to be certified in the coming weeks. The new blade is reportedly easier to manufacture, which is set to increase LEAP engine output. It is also expected to enable a 2.5X TOW increase compared to earlier engine models.

LEAP’s fleet size is projected to double by the end of the decade, with GE Aerospace expanding capacity to meet aftermarket growth. In particular, the firm is working to improve shop visit output and reduce turnaround times.

For instance, the Selma, Brazil-based MRO facility uses value stream mapping and problem-solving to cut LEAP test cycle times. After identifying waste and improving working standards, the facility reduced lead times by nearly 50%, contributing to the 20% increase in LEAP shop visits in Q3 2024.

Internal capacity is set to be increased through the $1 billion investment announced in July. Spread over the next five years, the funds will primarily be used to add new engine test cells and equipment to meet widebody and narrowbody growth.

GE Aerospace has also partnered with Lufthansa Technik to add a new LEAP MRO shop in Poland, which will take its first engine in Q4 2024. Additionally, the company is developing its third-party network to meet increased demand. Third-party MROs reportedly conducted a record number of LEAP shop visits in Q3 2024.

Culp is confident that these actions will allow GE Aerospace to increase LEAP output “meaningfully into the fourth quarter and 2025.”

3D printing commercial jet engines

GE Aerospace is not the only firm leveraging additive manufacturing for jet engine production. Earlier this year, South Dakota-based resin 3D printer manufacturer B9Creations was selected by aerospace manufacturer Consolidated Precision Products (CPP) to help accelerate ultra-precision jet engine turbine blade production.

Through the agreement, B9Creations is 3D printers, semi-custom hardware, and workflow management software tools. These are being used to scale the fabrication of high-pressure turbine components for next-generation commercial jet engines. Notably, B9Creations has supplied CPP with a suite of custom 3D printers designed to meet the build area and dimensional accuracy of turbine blade production.

Elsewhere, TCT 3Sixty 2024 saw GKN Aerospace’s Liam Pang outline the value of 3D printing for jet engine production. GKN-3D printed components are used on 100,000 commercial flights every day. These span 3D printing-enabled jet engines to DfAM-optimized hydraulic adapter blocks. According to Pang, “If you travel by plane today, you will likely encounter many GKN parts.”

He emphasized the sustainability benefits offered by additive manufacturing, with GKN able to “deposit the material where we need it.” This has allowed the company to reduce material usage by up to 80%, translating to a 90% reduction in material waste, and 35% CO2 savings.

Want to share insights on key industry trends and the future 3D printing? Register now to be included in the 2025 3D Printing Industry Executive Survey.

Nominations are now open for the 2024 3D Printing Industry Awards.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up with the latest 3D printing news.

You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Featured image shows GE Aerospace’s LEAP engine. Image via GE Aerospace.