Three years ago, a client turned to Avner Dei, 3DEImention CEO, seeking a metal printer capable of 5,000 parts per month. While the Desktop Metal P50 met the build requirements, its post-build depowdering proved laborious and expensive. To eliminate this bottleneck, Avner partnered with engineering experts to design a bespoke depowdering solution, cutting cleanup time in half and slashing operating costs.

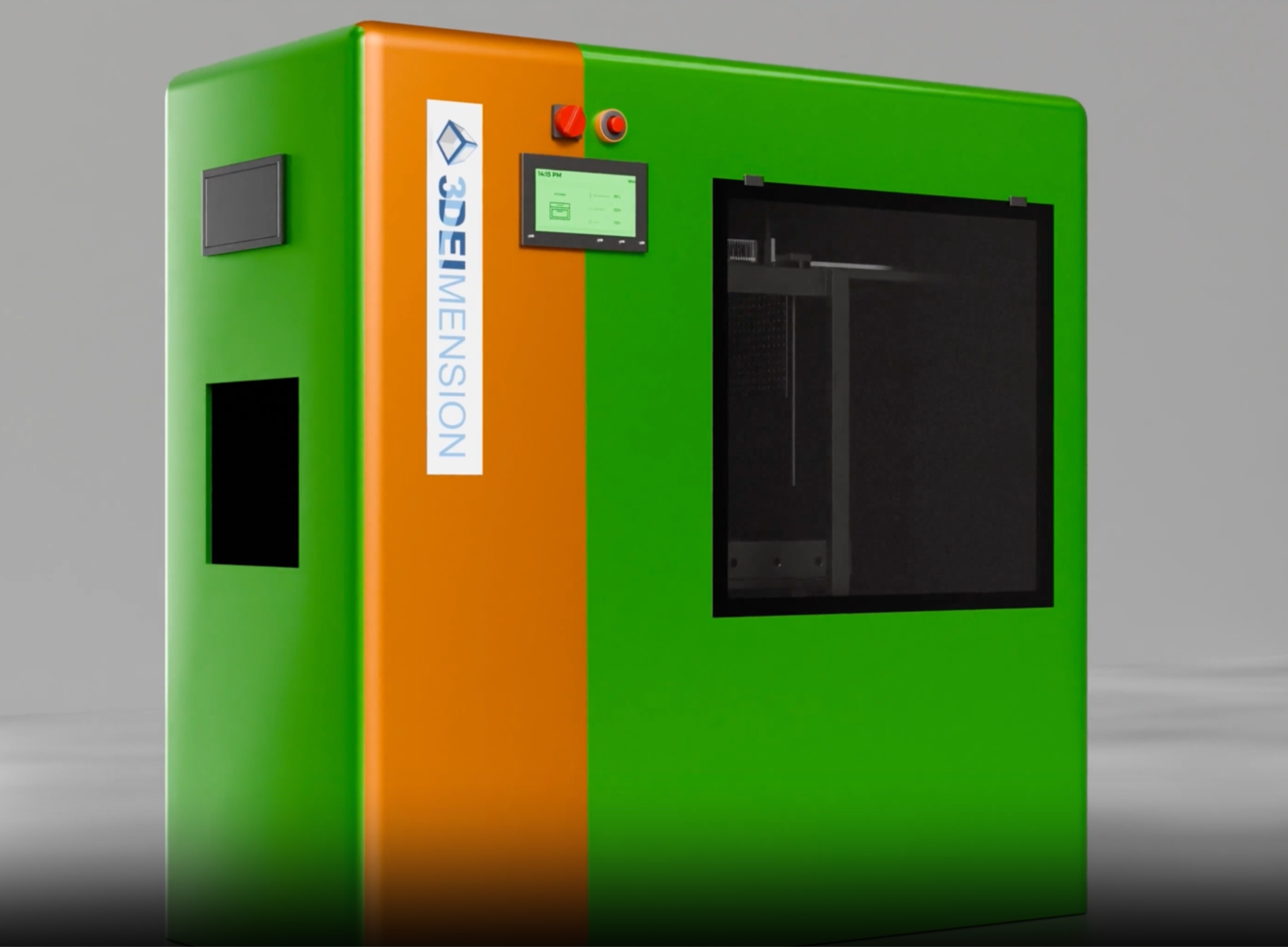

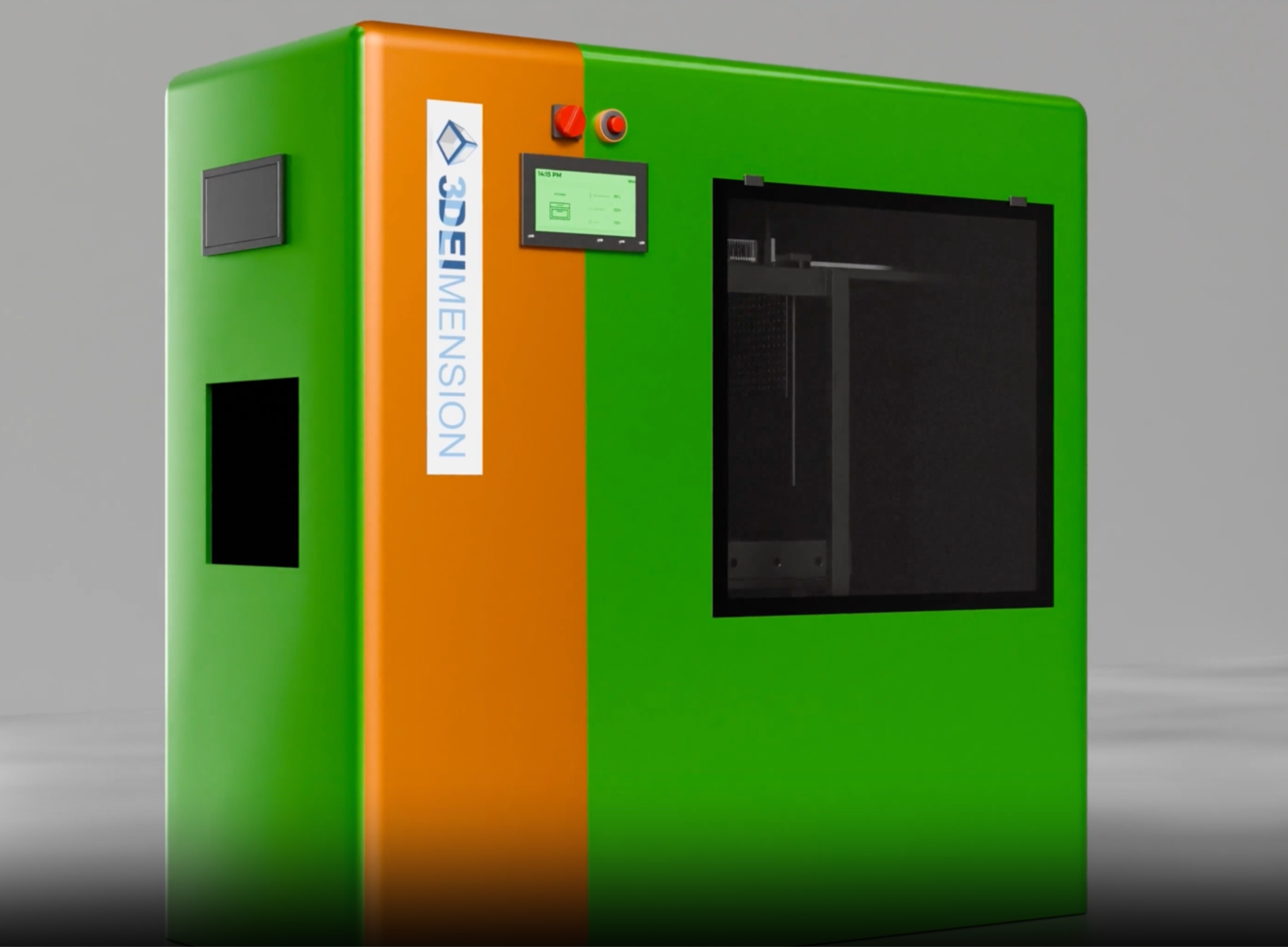

Today, 3DEImention introduces an automated solution for depowdering and extracting parts from additive manufacturing print beds. Designed to address the bottleneck of manual powder removal in mass-production environments, this system reduces labor, improves part quality, and recovers reusable powder in a single streamlined process.

Automated Workflow from Print Bed to Finished Part

3DEImention’s solution begins with a pre-programmed part-nesting process in which the build height is divided into layers. Those layers are transferred to the depowdering machine, where a motorized lift pushes the print-box floor up to the predefined layer height into an elevation frame featuring perforated side panels. Excess powder drains into designated collection channels beneath the frame, while a Teflon-coated partition is automatically inserted to maintain powder distribution and prevent damage to intricate surfaces. Once elevated, each layer undergoes targeted vibration and controlled air-pressure cleaning to dislodge adhering particles without marring fine geometries. A robotic gripper arm then rotates and transfers the parts onto sanitized trays, ensuring uniform cleaning and precise placement for downstream handling or inspection.

Precision Design, Sustainable Operation

Key innovations of the 3DEImention system include:

- Layer-by-Layer Depowdering: Programmable lifts sequentially present each printed layer to vibrating perforations, avoiding manual brushing and reducing cycle times by over 50 percent compared to standard workflows.

- Low-Friction Partitioning: The seamless movement of the Teflon-coated divider maintains a consistent powder bed height, protecting delicate features and enabling uniform cleaning across complex lattice structures or fine overhangs.

- Automated Powder Recovery: Unfused powder is channeled into an enclosed collection system where vacuum-assisted suction captures up to 70 percent of material for immediate reuse, cutting raw material costs and environmental impact.

- Multi-Platform Compatibility: While optimized for polymer SLS, the same process benefits metal powder bed fusion (DMLS, SLM, EBM) and binder-jetting workflows in polymer, ceramic, or metal powders; automating what was once a labor-intensive, manual cleanup step.

Measurable Gains in Production Efficiency

By automating the entire post-build sequence (layer separation, powder clearance, precision cleaning, and part extraction), 3DEImention’s system frees skilled operators to focus on quality control and value-added tasks. Manufacturers report:

Up to 70% Reduction in Depowdering Cycle Time: Faster turnaround from print to final part.

Up to 30% Powder Reclamation: Significant savings on costly polymer, ceramic, and metal powders.

Consistent Part Quality: Controlled cleaning parameters eliminate human variability, reducing part defects and rework.

Partnering and Investment Opportunities

Having validated their automated depowdering and part-extraction technology in controlled production environments, 3DEImention is now seeking strategic investors and industry partners to develop and deploy the first fully operated commercial machine. They invite additive manufacturing service bureaus, equipment integrators, and capital partners to collaborate on scaling this solution for global markets. Together, they can accelerate adoption, expand functionality, and customize the system to meet diverse production requirements.

For Inquiries and Further Engagement

3DEImention’s automated depowdering solution integrates seamlessly with existing print farms and post-processing cells. Interested customers can learn more or engage with the team by contacting Avner@3deimention.co.il or by visiting the website.

About 3DEImention

3DEImention specializes in robotic post-processing equipment for additive manufacturing. Combining expertise in automation, materials handling, and powder-bed technologies, the company delivers turnkey systems that enhance throughput, quality, and sustainability.